乳品處理

Driven by continuous innovation for over a century, Alfa Laval provides processing equipment that maximizes yield, facilitates easy cleaning, and minimizes waste at every step of dairy processing. Our components help you save on water, energy, and chemicals while meeting the strictest safety and hygiene standards. This way, dairies can make the most of every resource and create top-quality dairy products – with the flexibility and confidence to seize new opportunities in the market.

We help move dairy processing forward

More value from every drop

You can rely on Alfa Laval dairy processing equipment to get the most out of your milk – adding value at every step of your process. High-efficiency processing and gentle product handling secures better yield, reduced waste, and the highest possible product quality.

Furthermore, our innovative equipment designs and features enable extended production uptime with less time spent on cleaning and maintenance.

Built-in sustainability

Reducing energy, water, and chemicals consumption is at the center of Alfa Laval innovations, helping promote your sustainability efforts. We provide unique solutions that significantly lower the power consumption in your dairy. Likewise, optimized cleanability lets you reduce the amount of time, water, and chemicals spent on Cleaning-in-Place.

Superior hygiene

Hygiene is critical in dairy processing. Every detail of Alfa Laval hygienic processing equipment is designed with a strong focus on hygiene, to facilitate cleaning and reduce fouling. This makes it easier for you to meet the industry’s strict hygiene and food safety standards – today and tomorrow.

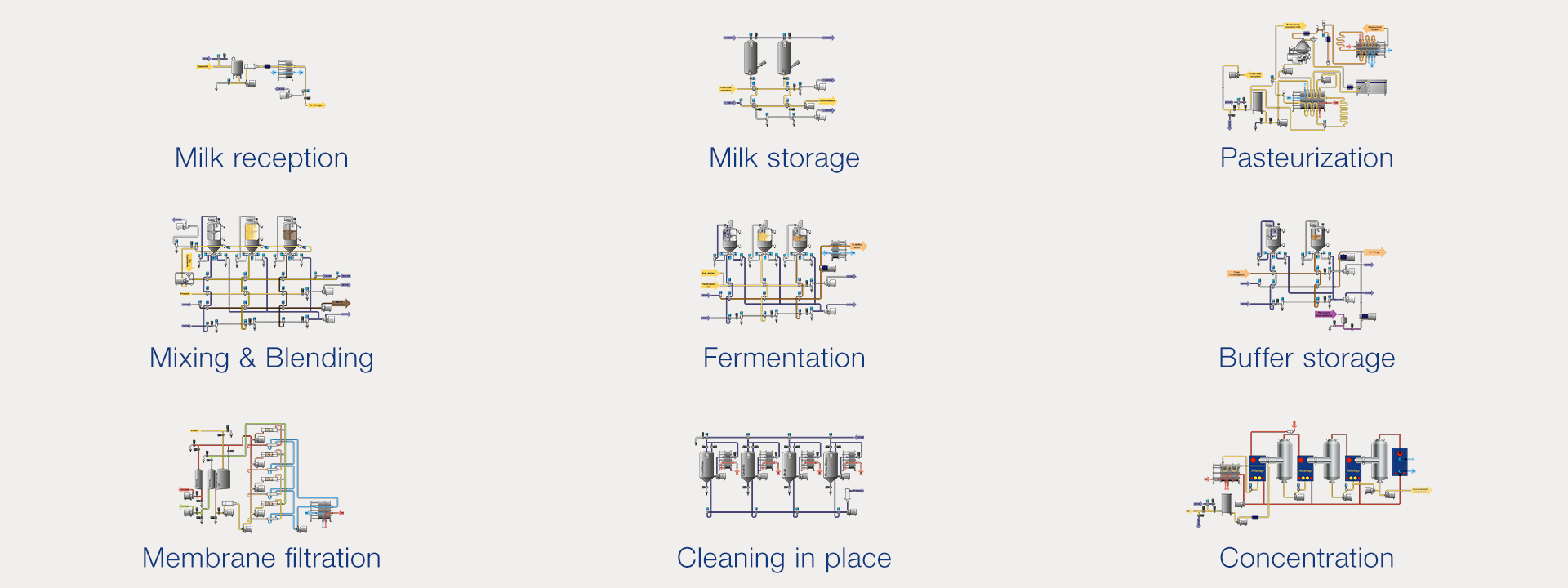

Optimizing every dairy process

From raw milk to finished dairy product, Alfa Laval components are designed to get the most out of every processing step. They help in maximizing yield, uptime, and product quality, while bringing power and water consumption to a minimum. Click on the button to view process steps and find highlighted technologies for dairy optimization.

Key products

We keep innovating. You keep improving.

Alfa Laval is here to help you stay at the forefront of dairy manufacturing. With deep roots in the industry, we are committed to finding smarter, better, and more efficient ways for you to produce top-quality dairy products. Throughout your equipment's lifetime, we offer our expertise and close collaboration to find the smartest upgrades and best ways of optimizing your dairy production. This includes digital solutions that help you stay in full control of your dairy processes.

Reduce your environmental footprint

Alfa Laval dairy processing equipment let you do more with less. They empower you to build a sustainable future for your business, while consuming less of the world’s precious resources. See some examples of how our products deliver value below.

Reduce energy: Hermetic Design & eMotion

With an airtight bowl improving the fluid dynamics, Alfa Laval dairy separators featuring Hermetic Design consume up to 60% less power than non-hermetic alternatives. By creating a near-vacuum around the separator bowl, the Alfa Laval eMotion module can increase energy savings up to 75%.

Reduce water: Thinktop

When it comes to water-saving innovation, the Alfa Laval ThinkTop stands out. When fitted on Unique Mixproof valves, the ThinkTop pulse seat clean function can save up to 95% of water and chemicals during Cleaning-in-Place.

Reduce chemicals: SaniSB

With Sani SB series rotary spray heads, dairy tank cleaning is more efficient than ever. The spray heads create a unique jet pattern, enabling up to 40% savings in time, water, and cleaning media.

Improve yield: Foodec

Purity and yield are the most important parameters during dewheying and dewatering in lactose and casein production. Alfa Laval Foodec decanter centrifuges are ideal for both, enabling up to 25% higher solids handling capacity than similar alternatives.

Service

Professional support right from the start

Backed by experience in servicing equipment for food, dairy & beverage applications, we are ready to support you whenever you encounter problems or wish to discuss upgrade opportunities in your dairy beverage production. We specialize in optimizing CIP programs to reduce water consumption and use of cleaning agents. Thanks to our global network of partners, field service engineers, service centers and spare parts distribution hubs, qualified help and genuine spare parts are always available.

We can support you from the initial installation and commissioning stage, and throughout the entire lifetime of your equipment with preventive maintenance, upgrades, remote monitoring, predictive maintenance, troubleshooting, and more.

Ensure maximal uptime, performance and return on investment. Learn more about the services we offer:

Decanter centrifuge services Hygienic pump services Heat exchanger services

Hygienic tank equipment services Hygienic valve services