Heating and cooling in the engine room

On a ship, there are many types of machinery with a cooling demand. When the heat energy cannot be recovered or utilized, the total costs of transferring it away from the machinery should be kept to a minimum. Alfa Laval can ensure a cost-effective central cooling system through our portfolio of innovative plate heat exchangers. Our gasketed plate heat exchangers have unique features that reduce the running costs for engine room cooling – and contribute to sustainability.

Central cooling system

Cost-efficient removal of excess heat

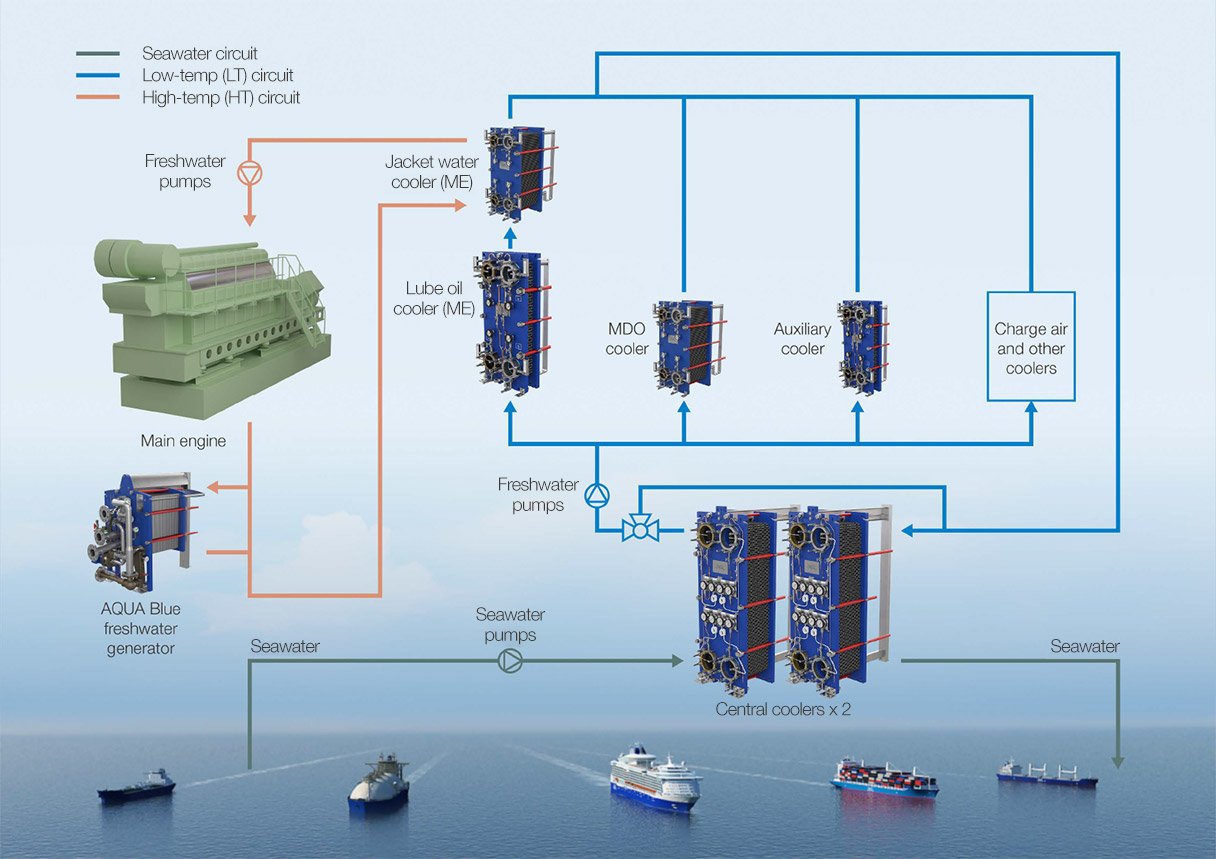

In the engine room, heat mainly needs to be removed from the jacket water cooler, lubricating oil cooler, diesel oil cooler and charge air cooler, along with the auxiliary engines and ancillary equipment.

The cooling flow of seawater is drawn from the sea chest. It passes through a coarse strainer to the titanium central coolers and thereafter overboard.

Fresh water is circulated through the central coolers, which are connected with a bypass regulation valve. The valve directs a portion of the fresh water through the coolers to maintain a constant temperature in the low-temperature circuit.

A portion of the excess heat generated in the jacket water circuit is used to generate fresh water in the Alfa Laval AQUA Blue freshwater generator.

Products

Services

船用設備技術服務網絡

無論何時何地,阿法拉伐船用設備技術服務網絡可即時回應您的需求,為您確保設備可靠運轉、最佳化設備效能,提供備品與技術支援。我們的全球技術服務團隊是您航向世界的最佳夥伴。