2015-06-01 Product News

Alfa Laval PureBallast augments IECEx certification with approval for use on barges in the U.S.

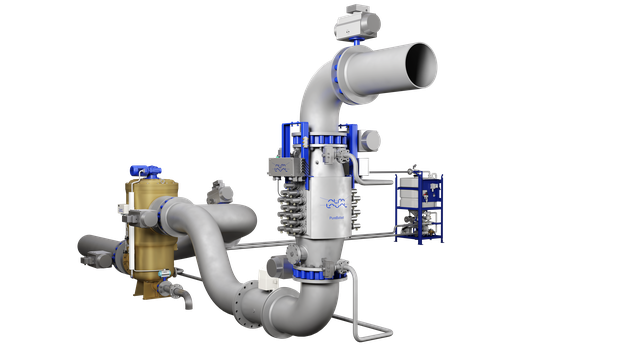

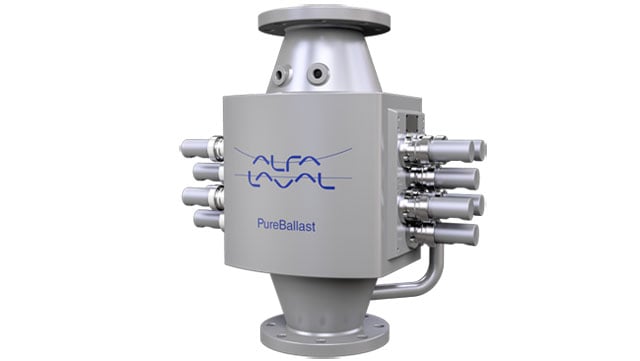

The explosion-proof version of Alfa Laval’s chemical-free ballast water treatment system, PureBallast 3.1 EX, has received approval from the U.S. Coast Guard for use on barges sailing in U.S. coastal waters. The approval comes a year after Alfa Laval PureBallast received an IECEx Certificate of Conformity from the International Electrotechnical Commission (IEC) for use in explosive atmospheres on board ships in international waters.

As a pioneer in the ballast water treatment arena, Alfa Laval introduced PureBallast, the first commercial chemical-free ballast water treatment system in 2006. Three years later, the company launched PureBallast 2.0 EX, which complied with ATEX directives, the European Union Directives for equipment use in potentially explosive atmospheres, such those on tankers carrying volatile cargo. Last year, PureBallast EX received an IECEx Certificate of Conformity from the International Electrotechnical Commission (IEC) for use in explosive atmospheres on board ships in international waters. Now this third-generation ballast water treatment system is approved for use on barge applications sailing in U.S. coastal waters, making it one of the first to be approved by the U.S. Coast Guard.

“We’re pleased that PureBallast EX meets the stringent criteria for approval by the U.S. Coast Guard,” says Alfa Laval’s Stephen Westerling Greer, Global Business Manager of PureBallast. “U.S. Coast Guard approval, together with IECEx certification, sends a strong signal to ship owners and operators that they can trust our ballast water treatment system to comply with strict national and international regulations while effectively cleaning ballast water.”

In addition to U.S. Coast Guard approval for use on barge applications, PureBallast EX comes with other noteworthy news regarding safety. To enhance safety onboard, Alfa Laval simplified the PureBallast design, enabling the lamp drive cabinets to be placed up to 150 meters away from the reactors they serve. This means the power supply can be safely located outside any potentially hazardous zone.

Westerling Greer says that there are other PureBallast innovations that enhance system performance, making it more attractive to ship owners and operators. These include 50% space savings, energy management and power ramp to optimize disinfection treatment whilst operating at full flow in low-clarity waters where UV transmittance is just 42%.

“We’ve also introduced a new PureBallast reactor for system sizes from 170 m3/h to 32 m3/h, our customers have access to leading edge technologies for a broader range of applications. Alfa Laval is now able to offer ship owners with vessels, large and small, the means with which to comply to international, national and regional regulations and local port requirements the world over.”