集熱式太陽能

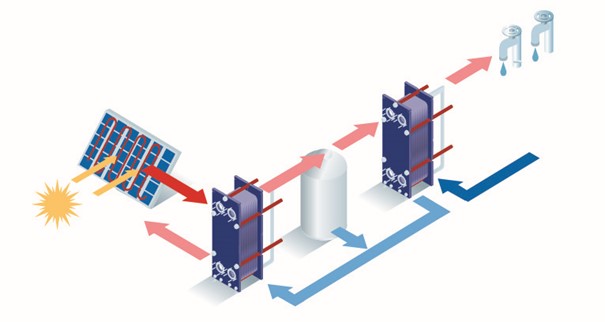

Transferring heat from solar collectors is an ideal way of using the sun’s energy. The sun’s heat is absorbed on a flat surface and then transferred to a fluid. The fluid can be used for heating domestic tap water and for radiator heating. In addition, it can be used for large-scale operations, like district heating, heating of process fluid in industries, or solar thermal power plants.

Choose the right solar thermal partner

- With a century of experience in heat transfer and energy efficiency, Alfa Laval has the products to ensure your system is as efficient as possible.

- The safe and reliable sealing of the gasketed plate heat exchanger means there is no risk of contamination of potable water in tap water heating.

- With an Alfa Laval heat exchanger, you maximize uptime with a reduced risk of fouling due to scaling.

- Our heat exchangers are AHRI third-party performance certified, so you can rest easily that the thermal performance is as good as we say it is.

- Alfa Laval’s global service network means we have the outreach and influence to ensure the continuous functionality of your equipment.

Trend in the solar thermal industry

The heating sector is currently dominated by fossil fuels for energy, with less than 20% of the global heating demand being met by renewable sources. This means there is huge potential for the growth of solar thermal energy as a source of heat.

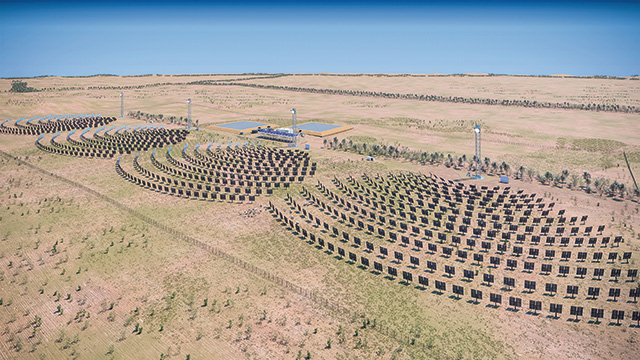

The interest in solar thermal heating has increased steadily over the past decade, and so has the cumulated solar thermal capacity. With this increasing interest, large-scale solar heating systems are becoming more popular, with district heating being the largest sub-sector. At the end of 2022, 325 large-scale solar district heating systems were in operation, with an installed capacity of 1,795 MWth.

The main challenges associated with solar thermal heating are fouling and the build-up of sediment. With Alfa Laval’s heat exchangers, this risk is substantially reduced with durable materials and turbulent flow. Our global service network can also ensure that your equipment runs optimally with minimum downtime.

A reliable partner, Alfa Laval shares our commitment to the global transition to renewable energy and has delivered superior heat transfer technology and expertise at our Carwarp power plant.

Richard Payne, CEO, RayGen

Solar thermal solutions from Alfa Laval

Tap water heating

In a solar water heating system, the main source of heat generation is solar panels that act as solar collectors. Since the amount of solar energy will vary throughout the day and year, a conventional boiler is often used as a backup. The collectors use the sun’s rays to heat a transfer fluid, which is usually a mixture of glycol and water. Adding glycol to the transfer fluid prevents it from freezing during the winter season. The transfer fluid flows in a closed-loop circuit that is separated from the water supply by a gasketed plate heat exchanger. After heating the tap water, the transfer fluid will circulate back to the solar collectors. With a gasketed plate heat exchanger from Alfa Laval, you ensure maximum heat efficiency and can rest easy that there is no risk of potable water contamination.

Space heating

Solar collectors in the form of solar panels can also be used for space heating. The collectors will heat a transfer fluid using the sun’s rays. The heat from the transfer fluid will then be transferred to the heating fluid in the secondary circuit using a gasketed plate heat exchanger. The hot fluid can be used to provide space heating through heated flooring, radiators, or forced hot air systems. Regardless of which, with an Alfa Laval heat exchanger you recover the maximum amount of heat, saving both energy and money in the process.

Large-scale solar thermal applications

Solar thermal power plants use the sun's energy to heat a transfer fluid to a high temperature. In order to extract maximum heat, they use mirrors to reflect and concentrate the solar radiation. This heat then needs to be transferred to water to produce superheated steam. The most efficient way to achieve this is by using a gasketed plate heat exchanger. The superheated steam is then used to turn turbines, converting mechanical energy into electricity.

半焊可拆板式熱交換器

- 高效可靠的技術,適用於各種因壓力或temperature fatigue而困擾的應用

- 獨特的Alfa Laval RefTight™密封系統,保證更長的生命週期

- 防止介質間的交叉污染,可靠的解決方案

顧問?系統整合商?

顧問們請不要錯過,憑藉在熱交換業界數十年的經驗,阿法拉伐為當今的供暖和降溫挑戰提供了豐富的知識底蘊。您可以在阿法拉伐找到關於能源效率以及天然冷媒等方面的複雜問題的解答,幫助您更輕鬆地找到適合應用的技術工具。

AHRI認證的熱交換器,確保可靠熱性能

我們取得全球對熱性能的AHRI(空氣調節、暖氣和冷凍協會)第三方驗證的認證,為您提供獨立保證,確保板式熱交換器將按照製造商公布的性能指標執行。阿法拉伐提供經過AHRI認證的墊片式板式熱交換器、銅焊式板式熱交換器和擴散焊全不鏽鋼板式熱交換器。

設備效能,歷久彌新

效能不佳的熱交換器,將對現場安全、產品品質和能源成本有負面影響。設備故障可能會導致代價高昂的非預期性停機和重大的生產損失。藉由定期檢測和主動維修保養,讓您可安心使用設備,輕鬆掌握運轉狀況。

數位化提升能源效益

智慧城市和數位智商有助於城市實現70%的永續發展目標。數位服務已經對城市的供暖和降溫系統帶來了顯著影響,向永續邁出一步。

啟用遠程監控並執行專用分析可實現更精確高效的營運、更明智的決策以及更有針對性的干預措施。唯有通過數位轉型才能發展更複雜高效的供暖和冷卻系統,可以為城市區域提供可靠且可負擔的供暖和降溫服務,同時一併減少溫室氣體排放。