Marine semi-welded plate heat exchangers

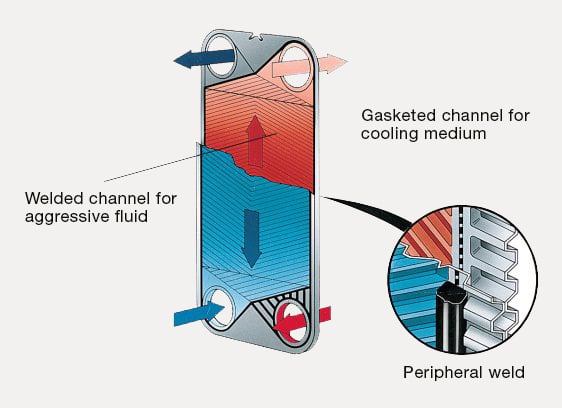

Semi-welded plate heat exchangers are suitable for fuel conditioning duties involving alternative fuels, LPG cargo handling duties, refrigeration duties and Organic Rankine Cycle (ORC) duties. Our marine line features the unique Alfa Laval RefTight™ sealing system, which guarantees a long lifetime sealing between the welded channels because the laser weld is on the outside of the ring gasket groove. The smooth surface ensures a tight uniform seal over the entire gasket ring.

Highly efficient and flexible marine heat exchangers

- High efficiency that reduces energy consumption and OPEX

- Long service life, comparable to the vessel lifetime

- Serviceable without hot work, protecting uptime

- Easy maintenance on board through CIP or mechanical cleaning

- Extendable capacity through the addition of plates

Alfa Laval’s marine semi-welded plate heat exchangers are available for a broad range of temperatures and media, with operating pressures up to 65 bar. Robustly constructed, they provide exceptional longevity with their resistance to vibrations and pressure cycles. The various sizes, which cover a wide spectrum of heat transfer capacities and flows, are carefully designed and selected to achieve optimal performance. The cooling media/seawater side is fully accessible without disconnecting the semi-welded plate heat exchanger from the pipework.

Documents

Downloads

Instructions and manuals

產業應用

機艙的降溫冷卻

多數船用設備都需要降溫冷卻,特別是整個船舶動力系統所在的機艙。而當機艙內的熱能無法回收或再利用時,則需盡可能降低移除設備運轉熱能的成本與效率。阿法拉伐的板式熱交換器產品組合可提供多種選擇,確保中央冷卻系統高效運轉且兼具成本效益,以降低機艙降溫冷卻的總體營運成本,有助於實現永續目標。

Heating and cooling for LPG cargo handling

The transport of LPG requires tailored cargo handling systems. Alfa Laval marine semi-welded plate heat exchangers are the ideal choice for the cargo condenser, thanks to their very high efficiency, their small footprint and the ease of performing service on board. The robust units resist vibrations and pressure fatigue, and more plates can be added if faster loading rates are desired.

甲醇燃料用熱交換器

隨著船舶航運產業的去碳化進程逐步推動,首批以甲醇為燃料的船舶陸續問世,業界對甲醇燃料的興趣也與日俱增。甲醇是一種可燃燒的液體燃料,若以潔淨技術產製,則可望實現碳中和。然而,與傳統的化石燃料相比,甲醇在供熱製冷的應用上卻面臨挑戰。阿法拉伐的甲醇燃料專用熱交換器產品系列,可確保其安全且高效率地在船上應用。

船用冷凍系統

冷媒在航運業中十分常見,從漁獲冷藏冷凍系統到郵輪上的空調設備,應用極為廣泛。然而,冷媒的種類正迅速變化。過去使用的氯氟烴(CFC)和氫氯氟烴(HCFC),已被氫氟烴(HFC)冷媒取代。如今,亦有越來越多的船東開始採用二氧化碳等天然冷媒。阿法拉伐具完整熱交換器解決方案和應用知識,可協助產業用戶因應不同冷媒選擇。

Services

船用設備技術服務網絡

無論何時何地,阿法拉伐船用設備技術服務網絡可即時回應您的需求,為您確保設備可靠運轉、最佳化設備效能,提供備品與技術支援。我們的全球技術服務團隊是您航向世界的最佳夥伴。

Higher pressures demand a higher standard

If your heating and cooling duties demand higher pressures, it’s time to demand a higher standard of technology. Discover total reliability and efficient thermal performance with the Alfa Laval marine line of semi-welded plate heat exchangers.

Highly efficient with unique sealing system

Alfa Laval marine semi-welded gasketed plate heat exchangers are suitable for liquids and gases incompatible with normal gaskets or at higher pressures. They are commonly used in refrigeration applications for evaporation and condensation.

The unique Alfa Laval RefTight™ sealing system guarantees a long life-time sealing between the welded channels because the laser weld is on the outside of the ring gasket groove. The smooth surface ensures a tight uniform seal over the entire gasket ring.

What make our plate heat exchangers so reliable, efficient and serviceable?

Equipped with well-designed features that make a difference, Alfa Laval marine semi-welded plate line of heat exchangers are easy to maintain and have a long service life.

RefTight™

RefTight™

高性能密封系統

高溫高壓下仍保持絕佳密封能力,可延長墊片使用壽命

CurveFlow™

CurveFlow™

最佳化介質流動

妥善運用板片分流區域,達到介質流動最佳化,降低結構風險

OmegaPort™

OmegaPort™

非圓形出入口設計

非圓形的出入口設計減少壓降,促進板片表面積利用率

ClipGrip™

ClipGrip™

墊片緊固設計

實現墊片的精準定位,易於板片安裝與鎖緊,防止變形

Five-point alignment

Five-point alignment

Ensures reliable plate positioning and easy service of large units.

T-bar roller

T-bar roller

Provides a lower unit that is easy to service.

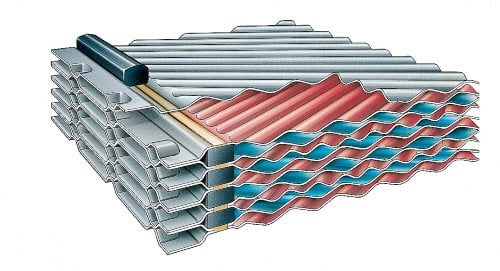

The heat transfer area of a gasketed plate-and-frame heat exchanger consists of a series of corrugated plates, assembled between the frame and pressure plates, which retain the design pressure. For the highest thermal performance and to enable a very close temperature approach, fluids normally run counter-currently through the heat exchanger.

The sealing between the plates on the marine semi-welded line alternates between laser welds and gaskets. The laser welded channel allows use of fluids that are not compatible with normal gaskets and also allows for higher design pressure than fully gasketed plate-and-frame heat exchangers. Additionally, the Alfa Laval RefTight™ sealing system guarantees equal sealing force over the entire porthole gasket.

The marine semi-welded line is available with various pressing depths and angles of the chevron pattern and various shapes of the corrugation which are carefully designed and selected to achieve optimal performance. The CurveFlow™ and the chocolate pattern distribution area are two design features available that ensure fluids are evenly distributed across the entire plate. The result is that the entire heat transfer surface is fully utilized and stagnant zones that can result in fouling are avoided.

High flow turbulence between plates results in higher heat transfer; however, the consequence is pressure drop. Our thermal design engineers will help you design and select the model and configuration that is suitable for your application needs while delivering maximum thermal performance and minimizing pressure drop.

Liquid/Liquid GPHE

Steam Heater GPHE

>