工業用水及汙水處理

The transition to more circular business models is essential for being able to operate in a more sustainable way. As industrial processes use significant amounts of water, becoming more circular means first understanding how this water can be treated so it can be saved and reused. Then investing in methods which allow you to reuse, recycle or sell waste by-products from this water treatment can lead to cost savings and/or an additional revenue stream.

Alfa Laval enables you to reach your net zero emission goals by:

- Maximizing reuse of water

- Turning waste into value

- Minimizing energy consumption

- Reducing waste volume

- Reducing footprint

Applications overview

Alfa Laval offers a wide range of solutions within water and waste treatment for many industries and many applications. Learn how you can benefit from water and waste treatment within your specific application.

Pulp and paper

The production of pulp and paper requires large quantities of water for virtually all the processes involved. Even with some recycling, pulp processing and paper making still require large quantities of fresh water. Alfa Laval provides both the process equipment and the know-how to help you minimize water consumption and optimize the economics of your wastewater treatment.

Steel and COG

Decanter centrifuges are widely used for dealing with dust arising from blast furnaces, basic oxygen furnaces, sintering plants, and other molten metal operations. Removing water from the wet scrubbing slurries and recovering and recycling the resultant solids make it possible for you to generate important additional revenue flows. Alfa Laval decanter centrifuges are also used extensively for dewatering sludge that result from wastewater treatment operations prior to disposal so that the water can be reused.

Power

The combustion of coal in power generation facilities produces SO2 that is emitted to the atmosphere. Flue gas desulfurization (FGD) is widely used by power plants to remove SO2 from flue gas. Wet scrubbing by limestone, the most common technology used in FGD system, generates gypsum as a by-product as well as wastewater which both need to be treated prior to reuse or disposal. Alfa Laval decanter centrifuges are a proven solution for gypsum and wastewater sludge dewatering.

Chemicals

The production of chemicals generates a significant amount of wastewater that is mainly coming from aqueous discharges of manufacturing processes. Discharges from equipment and production workshop washing and cleaning and collection of rainwater from contaminated areas are also generated. This wastewater contains pollutants that must be treated before it can be discharged to the environment or recycled and reused in the process. Alfa Laval decanter centrifuges provide cost-effective solutions in the dewatering of sludge generated from wastewater treatment operations.

Oil and gas

The oil and gas industry generates a significant amount of wastewater from upstream and downstream activities which must be managed. Produced water is the largest waste stream generated. Produced water and other waste streams are contaminated with organic and inorganic pollutants that need to be treated before it can be reused, recycled or released into the environment. Alfa Laval decanter centrifuges provide cost-effective solution in the recovery of oil from waste stream such as slop oil and dewatering of sludges generated from wastewater treatment operations.

Textiles

The cleaning and processing of plant and animal fibres, typically cotton and wool, produce effluents especially during washing, spinning, processing, bleaching and dyeing. The waste sludges need to be dewatered to reduce disposal costs, and decanter centrifuges are usually the most economical solution. Alfa Laval decanter centrifuges are a proven solution for dewatering textile sludge produced in the process waste stream.

Manure

Animal manure from intensive agricultural operations, transportation marshalling points and winter housing is readily processed with decanter centrifuges. They offer good recovery of phosphorous in the cake and a liquid stream of high-nitrogen liquid fertilizer, both of which are generally acceptable for land application. Alfa Laval Decanter Centrifuges are a proven solution for dewatering manure sludge.

Dredging

Dredging of inland waters to remove effluent disposal or improve navigation will produce a range of sludge from fine sand to organic sludge similar to Anaerobically Digested Municipal waste. These sludges are readily dewatered by decanter centrifuges prior to transport and ultimate disposal. Occasionally, previous industrial use will leave sediments with significant contamination requiring specific waste treatment. Alfa Laval decanter centrifuges are used to dewater dredging sludge for disposal to land fill or for land fertilizer application depending on the requirements.

Brewery

Beer production has three large waste streams: spent grains, spent yeast and Kieselguhr/Perlite. Dewatering of grains and yeast increases the value of these two products which are mainly used for animal feed. If they are enzymatically or chemically treated, washed, concentrated and dried in a hygienic process, the resultant protein-rich products could also find a value-generating outlet in the food industry. In some countries, breweries dewater Kieselguhr/Perlite to increase its dry matter content to prepare it for disposal. Dewatering brewery waste streams with decanters reduces volumes of waste and can also result in considerable savings in transport costs. Alfa Laval decanter centrifuges are a proven solution for dewatering of the three waste streams in breweries

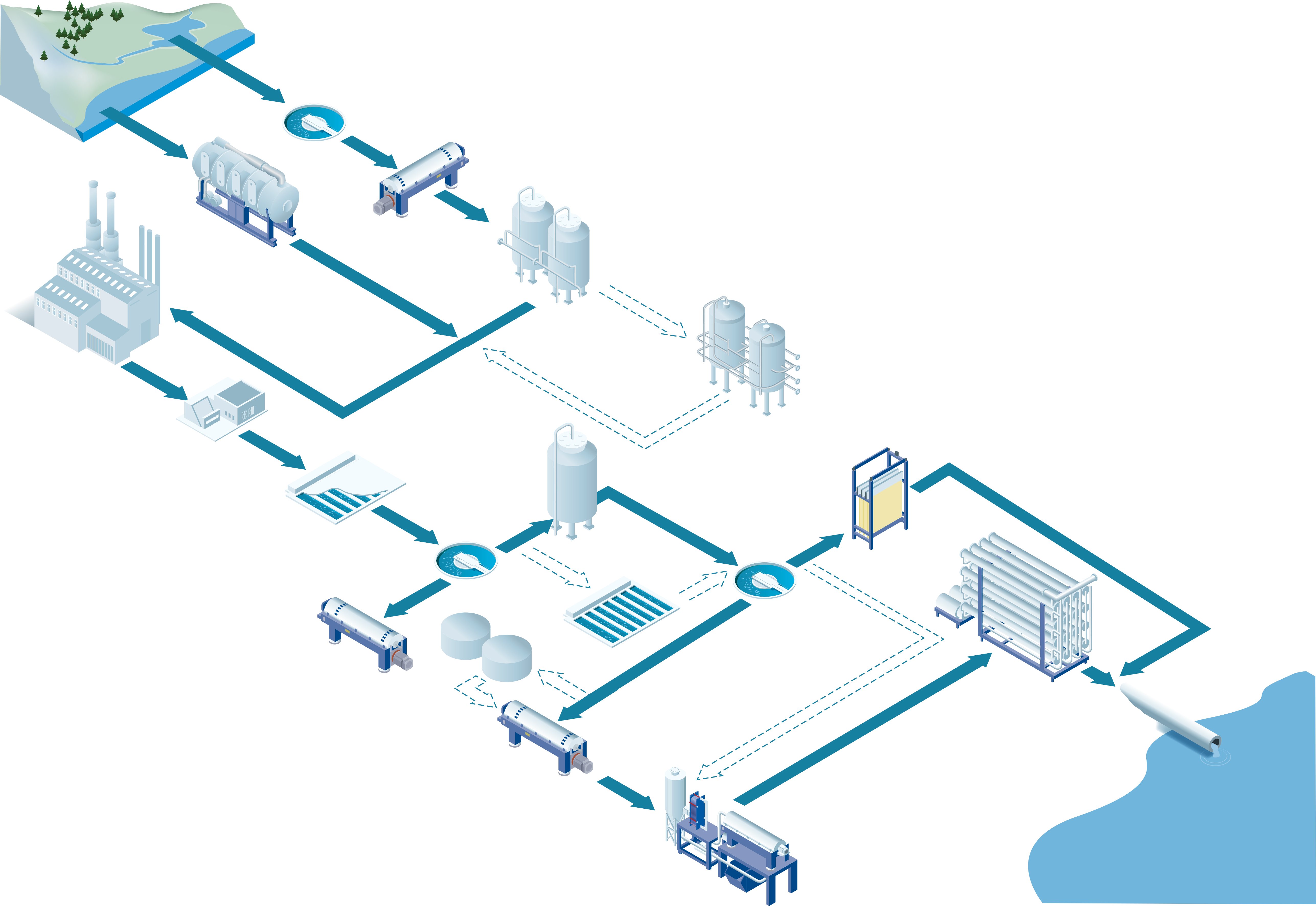

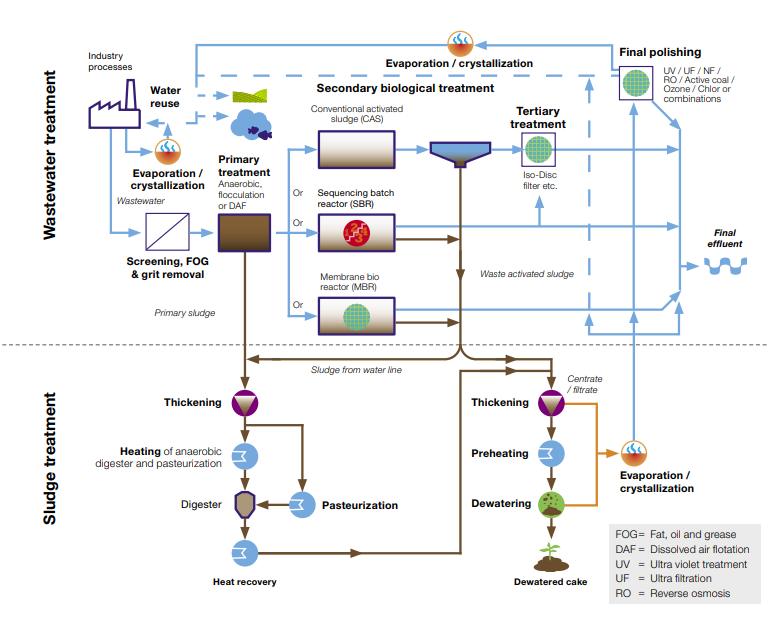

Process overview

With Alfa Laval as your partner, you gain the dual advantage of access to leading wastewater expertise as well as one of the broadest equipment ranges for wastewater treatment.

Sludge thickening

Sludge dewatering

Wastewater filtration

Zero Liquid Discharge

Improve your efficiency and sustainability with world-leading solutions from Alfa Laval

Read the brochure to find out how you can recover valuable material in the waste that otherwise would have been lost by applying a thorough separation process and by reusing the water. Alfa Laval has the range, knowledge and expertise to be able to provide the right solution for your specific requirements.