Committed to circular carbon

Carbon is the cornerstone of the chemical, fuel, and plastics industries. Today, most of it comes from fossil sources. We need to adopt a circular carbon approach to make our industries sustainable, by using carbon from sources such as captured CO2, biomass, and recycled materials. This process, known as defossilization, is the key to achieving a circular economy for carbon. Although the circular carbon industry is young, Alfa Laval has more than 70 years of experience with the technologies needed to accelerate the shift from fossil to circular carbon.

With over a century of expertise in processes from various industries, Alfa Laval offers you:

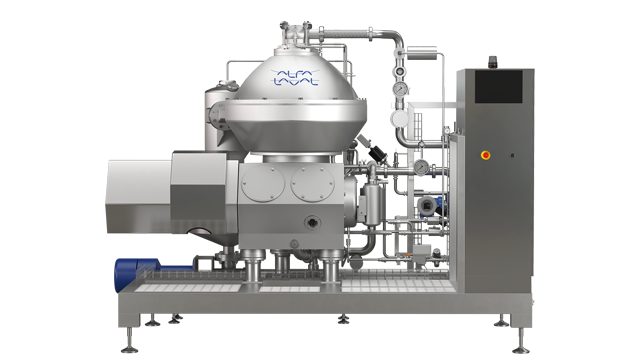

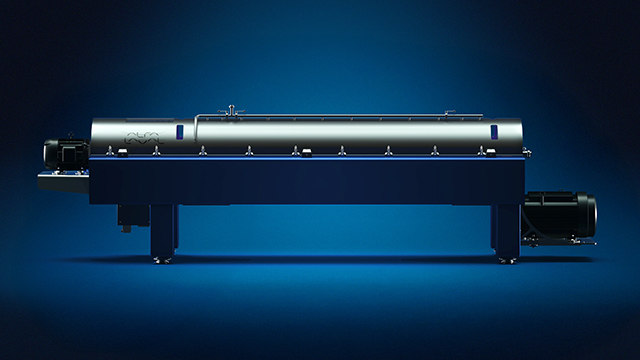

- Advanced downstream separation

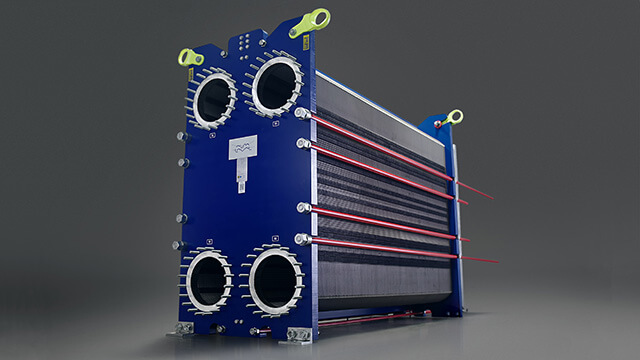

- Efficient energy integration

Why defossilization is needed in the material and chemical industries

To reach the Paris Agreement's net-zero targets, the world’s industries must become carbon neutral by 2050. The energy sector is already transforming by decarbonizing—stopping the use of carbon-based fuels and focusing on solar, wind, and hydropower. New energy carriers like hydrogen, along with energy recovery, saving, and storage, are making the energy sector fossil-free and decarbonized.

However, for chemicals and materials, decarbonization is not an option as carbon is the heart of these products. Instead, we must defossilize—stop using fossil carbon and switch to circular carbon.

![Renew Energy+Carbon high[47]](https://www.alfalaval.tw/globalassets/images/industries/energy/cleantech/circularity/circular-future/renew_energycarbon_high47.png)

Net zero event: Accelerating the shift from fossil to circular carbon

In the event, leaders within the fuels, chemicals, and materials industries will share insights and best practices that will help us accelerate the shift to a circular carbon economy. The event is now available on-demand!

Committed to circular polymers, fuels and chemicals

Alfa Laval has decades of experience in the separation and heat transfer technologies needed, both in fermentation and thermochemical processes. We offer cutting-edge solutions and expert advice for downstream separation, energy, and water integration, helping you plan and produce circular chemicals, liquid fuels, and plastics. By leveraging the unique Alfa Laval products, know-how, test capabilities and services, we help our customers to cut cost, risk and development time.

Circular polymers

Feedstocks like biocarbon or recycled carbon will be essential for defossilizing the polymer industry. Biopolymers, such as PHA, PLA and PEF, are polymeric materials produced from renewable biomass sources, often through industrial fermentation. They offer a more sustainable and circular solution to conventional petroleum plastics.

Circular fuels

In the quest for sustainable energy solutions, the future is increasingly oriented towards biofuels, such as bioethanol and biodiesel. Biofuels that are derived from renewable sources like biomass, grains, seeds, and cellulose, help reduce the reliance on fossil fuels. The aviation industry is on the same quest, actively seeking sustainable aviation fuels (SAF) to reduce its carbon footprint.

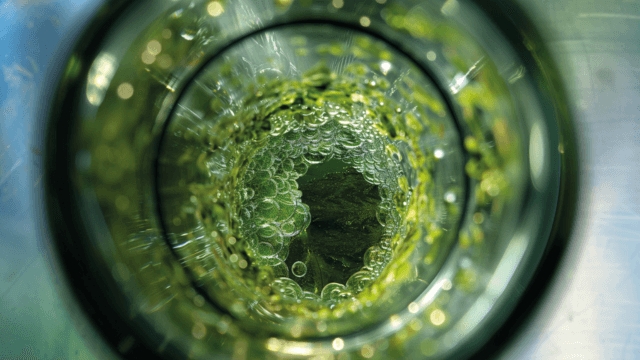

Circular chemicals

Chemicals produced from biomass and recycled sources play an important role in reducing our dependence on fossil resources. Trees, plants, crops, algae, bacteria, and biological waste can be used to produce a wide range of circular chemicals. BDO, PDO and MEG are some examples. The transition to circular carbon in the chemical industry will have a big impact on the entire value chain, since more than half of the chemical production is an input to other industries.

Recycled carbon

Recycled carbon is projected to account for 55% of the carbon molecules in chemicals production by 2050. Technologies that enable and complement conventional recycling methods, like mechanical recycling (PET), will push the transition to sustainable materials.

Downloads

Whitepaper: Accelerating bioprocess development and scale-up

Fast technological advances in biomanufacturing are revolutionizing the industry by significantly enhancing production efficiency, quality, and scalability. Partnering with a reliable industrial partner is essential for successful biomanufacturing because they provide the expertise, resources, and scalability needed to navigate the complexities of scaling up production.

Whitepaper: Optimizing the upgrading process of your pyrolysis product

By 2050, over 50% of the carbon in chemicals is projected to come from recycled sources. Pyrolysis is identified as a promising technology for converting waste into valuable pyrolysis oil (pyoil). However, pyrolysis processing faces challenges such as high viscosity, water content, low heating value, and stability issues.

Videos

Clean technologies for a circular tomorrow

Heat transfer in biopolymer production

Downstream separation in renewable polymers

Alfa Laval spiral heat exchangers

Improving the sustainability and profitability of renewable diesel production

Applications

Many renewable processes rely on separation to reach high product purity, high product recovery and optimized use of water and energy. In addition, energy efficient heat transfer is key. At Alfa Laval we have decades of experience that we can apply to your circular scale-up. Below are some examples of processes where we can make a difference.

Biopolymers

Biopolymers are plastic materials produced by industrial fermentation from renewable biomass sources instead of fossil fuels. In the race to reach our collective sustainability goals, biopolymers are being used as a more circular solution to conventional petroleum plastics.

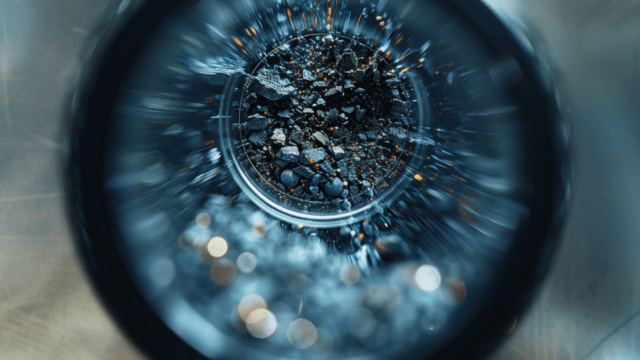

Plastic and tire recycling via pyrolysis

Recycling enables the conversion of low-value waste, such as plastic, tires and biowaste into new materials. This makes pyrolysis the dominant recycling technology for the future.

HVO

Alfa Laval HVO pretreatment systems enable the production of renewable diesel and sustainable aviation fuels from a wide range of fats and oils, including recycled animal fat and used cooking oils.