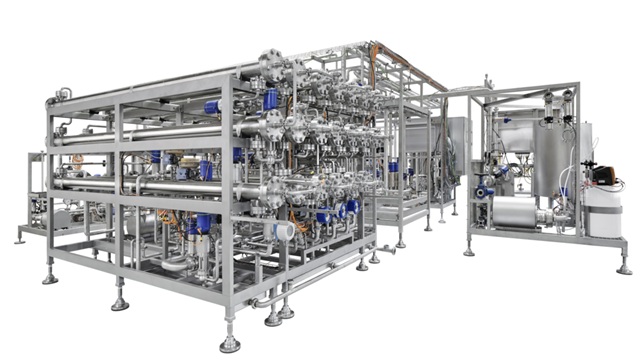

Revos concentration system

Alfa Laval Revos™ concentration system uses high-pressure, low-temperature reverse-osmosis technology to remove water from beer, wine and cider after fermentation to produce a quality concentrate with up to 22% alcohol by volume (ABV). When rehydrated it has the same taste, aroma, minerals and alcohol content as the original product.

Compact, economical and energy-efficient beer and beverage concentration system

- Up to 80% lower transport costs due to reduced concentrate shipping volumes for rehydration at bulk packaging facilities or at points of sale

- Save valuable floor space at the point of sale, such as bars and restaurants, by rehydrating concentrate only at the time of serving

- Preserve the flavour, aroma, minerals and alcohol content of the original beer or beverage due to low-temperature, patented two-pass processing

- Highly versatile system for beer and beverage concentration

Increase stability while reducing distribution and shipping costs with the Alfa Laval Revos beer concentration system.

How does the Revos beer concentration system works

Revos uses a patented two-pass reverse osmosis process engineered to produce premium beer concentrate from both alcoholic and non-alcoholic beer.

In the first pass, chilled beer passes through proprietary membrane elements under high pressure. Water permeates the membranes, while alcohol, proteins, sugars, aromas, and minerals remain in the beer concentrate. In the second pass, the system recovers and retains the alcohol and aromas that are then recombined with the concentrate, ensuring the final concentrate matches the original beer specification.

The result is a high-quality beer concentrate that remains stable during packaging, storage, and transportation until it is rehydrated back into the original beer.

From concentrate to fresh beer - bottled or on draft, just like the original

Bulk transport and rehydration

Transport beer concentrate in bulk. Rehydrate bulk shipments at a designated facility, then package reconstituted beer into kegs, bottles, or cans.

Direct-to-keg

Ship beer concentrate in kegs directly to restaurants, pubs, or bars and rehydrate on site with a draft system.

Non-alcoholic beer

Handle non-alcoholic beer concentrate the same way as concentrate with alcohol. Rehydrate it using a draft beer system, or add water and bottle it for sale.

Draft dispense system

Ensure perfect taste and temperature with on-demand rehydration. Alfa Laval and Micro Matic offer a compact, draft beer dispensing system that blends cold, carbonated water with alcohol concentrate or non-alcoholic concentrate.

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems

Learn more about our service offer for food systems

Validate what Revos can do

Take the guesswork out of scaling beer production. Send 850 litres of your beer to the Alfa Laval Revos Innovation Centre in Copenhagen for a controlled lab trial. We’ll concentrate it without altering your recipe, and quality will be independently verified by VLB Berlin (on demand).

Prefer on-site testing? Rent a beer concentration system (6hl/hour inlet capacity) at your own brewery to evaluate performance under real operating conditions. The result? Proven taste, reliable economics, and a clear business case for rollout.

Revos questions? We’ve got answers

Find answers to the most frequently asked questions about the Revos beer concentration system here.

Curbing carbon emissions - Learn more from our white paper

How can breweries and beverage manufacturing facilities reduce their carbon footprints while making operations more efficient? Reducing direct and indirect emissions plays an important role – from purchasing raw materials, electricity and manufacturing to packaging, materials and distribution. This white paper will focus on reverse osmosis (RO) membrane filtration for beer and beverage concentration as a cost-effective way for manufacturers to reduce the carbon footprint of their supply chains.