Carboset

阿法拉伐 Carboset™ 和 Carboset™ Mini 是啤酒碳酸化系統,非常適用於精確、自動和低維護的啤酒碳酸化和其他飲料(包括軟飲料)的碳酸化。 我們的啤酒碳酸化器專為滿足啤酒中所需的二氧化碳水平以及啤酒中氮的需求而設計,以符合您的完美配方。

An efficient, automatic and robust carbonation machine

- Eliminates the risk of bubble formations

- Outstanding blending accuracy

- Efficient dissolving of carbon dioxide

- Versatile and adaptable to different process requirements

- Automatic control and low maintenance

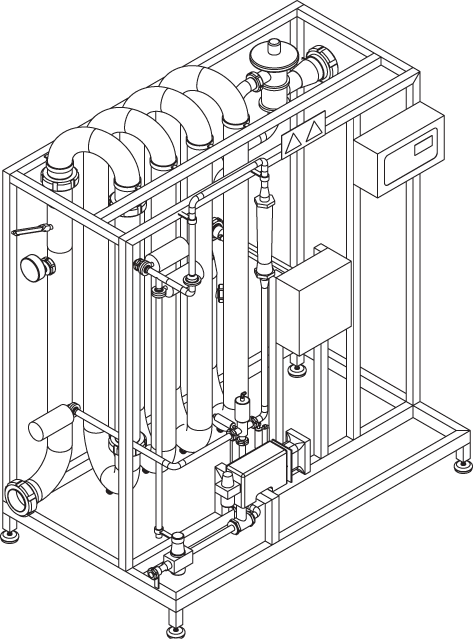

Carboset™

Carboset™ 是與釀造業合作開發的飲料系統和供給之一。 它是一種久經考驗的、堅固、緊湊的啤酒碳酸化模組,是一個可靠、高效和衛生的解決方案,可提高啤酒和其他飲料的品質。

尺寸*

- (長 x 寬 x 高):1.5 米 ×1.0 米 ×2.3 米 出口處的

- CO2:最多 7 克/升(最終產品)

*確切的尺寸取決於容量範圍。

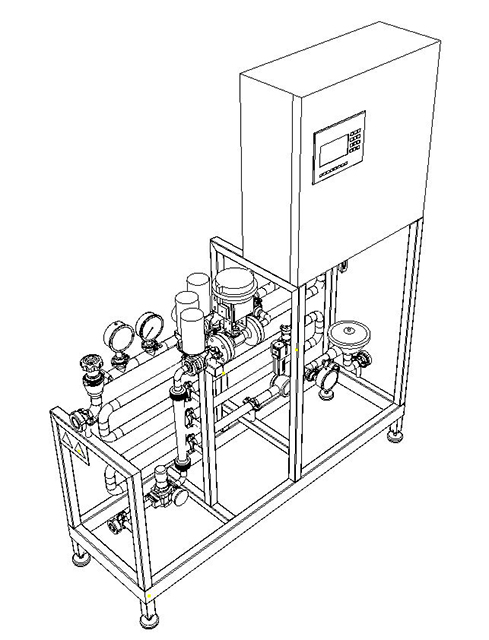

Carboset™ Mini

設計時考慮到精釀啤酒廠。這個特別模組可以幫助您在啤酒中獲得適當水平的二氧化碳,並解決啤酒中二氧化碳濃度低或不一致的問題。 您可以在 Carboset™ Mini 中存儲多種配方,並為不同的啤酒和灌裝線提供個性化設定。

尺寸*:

- (長 x 寬 x 高):1,600 x 500 x 2,000 mm

- 出口處的 CO2:4-6 克/升

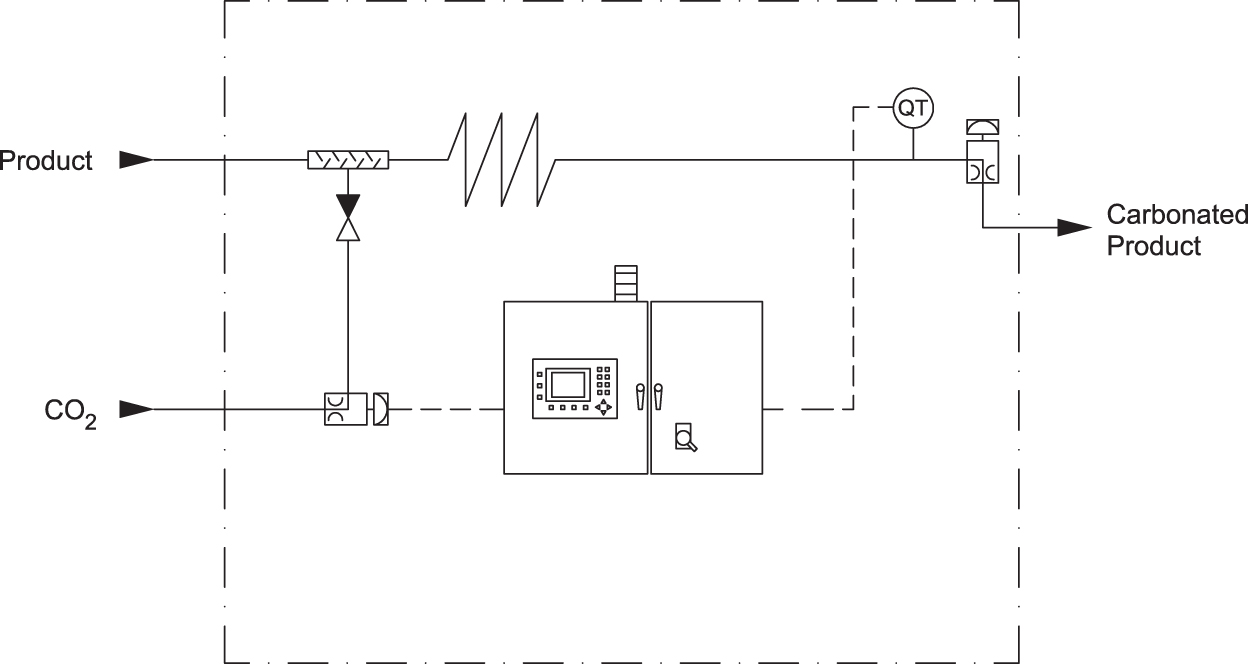

工作原理

碳酸化系統如何運作

在啤酒中實現所需且一致的二氧化碳濃度並不困難。 使用我們的碳酸化系統,CO2 通過一個專門設計的靜態混合器直接注入啤酒,這確保氣體能夠有效地溶解。 在控制面板上設定所需的碳酸化水平,流量計、CO2 計和控制閥可確保加入確切的氣體量。

該模組包括與背壓閥組合的保持單元,因此當啤酒離開模組時,所有氣體都完全溶解。

典型應用可能是在 2℃ 的溫度和 4 巴(g)的壓力下將進入的啤酒碳酸化為 CO2 含量恰好為 6.0 克/升。

FAQs

Can an Alfa Laval Carboset™ operate in front of a filler and/or without buffer tank?

Yes. It is important to note that, in doing so, there is a risk of variations in the CO2 content when the filling line is stopping and starting. However, the risk is minimized due to the usual presence of the buffer volume in the filling machine.

Is it possible to install a Carboset just after a separator?

Yes, however the Carboset must be able to communicate with the separator in order to handle the interruption in product flow during discharge. Before the separator discharge, the Carboset memorizes and saves the position of the CO2 dosing valve, and initiates the same dosing conditions as soon as the flow of product begins again.

How quickly can I change the CO2 concentration in the product?

The CO2 setpoints for different recipes are stored in the Carboset control unit. To change the CO2 concentration in the product, you simply need to choose the recipe that corresponds to the concentration that you want to use. This only takes a few seconds.

Service

Food system services

Alfa Laval Food system services help extend the performance of your food systems by maximizing the performance of your processes. This enables you to:

- Continually improve your operations to maintain competitive advantage

- Focus on uptime, optimization and availability

- Maximize return on investment throughout the life cycle of your food systems