薄膜過濾系統

Alfa Laval designs, manufactures and installs complete cross-flow membrane filtration systems, based on polymeric membranes. Our production units are based on either the unique plate-and-frame modules or on spiral elements of varying sizes. For some applications, a combination of both types can be used to give the best possible solution

Long experience and complete membrane filtration system range

- Lower overall production costs

- High end product quality

- Customized design

- Customized design

- 24-hour service programme

Alfa Laval offers a complete range of cross-flow membrane filtration solutions and in-house membrane manufacture. Our experience in microfiltration, ultrafiltration, nanofiltration and reverse osmosis dates back as far as the mid-sixties, soon after membrane filtration was introduced on a commercial scale.

The extensive Alfa Laval portfolio of membrane filtration equipment includes high performance polymeric membranes, sanitary modules, components, laboratory test units, pilot plants and fully engineered membrane production units.

Our membrane solutions, when used in industrial-scale applications where reliability, consistency and operating costs are crucial considerations, offer significant advantages.

Customized membrane solutions

We take pride in supplying our customers with complete, optimized membrane solutions that take every aspect of the process into consideration. Our solutions are designed on the basis of feed product composition, production parameters, final product requirements and costs. The membrane solutions then selected can be based on the unique plate-and-frame modules or the cost effective spiral elements - or a combination of both to give the best possible solution. We develop our membrane filtration systems in close cooperation with customers and can provide batch and continuous operation as well as sanitary and industrial design. Validation support is available, as is support in installation and commissioning.

Membrane filtration and separation technology from Alfa Laval

Membrane filtration complements the range of other separation technologies offered by Alfa Laval. This ensures that we are always in a position to provide you with the ideal solution for your particular process. By using membrane filtration alone or in combination with our range of centrifuges, decanters or evaporators.

How does membrane filtration work

Physical separation

Membrane filtration is a physical separation process in which the driving force is the difference in pressure between the two sides of a special membrane. This process is characterized by the ability to separate molecules of different sizes and characteristics.

Almost all industrial membrane filtration is carried out as cross-flow filtration, where the liquid being filtered flows parallel to the membrane at high velocity and under pressure.

Physical barrier

In its most basic terms, membrane filtration involves passing a single feed stream through a membrane system that separates it into two individual streams, known as the permeate and the retentate. The membrane that separates them is a physical barrier with highly specialized characteristics - a barrier that only certain selected components in the feed stream can pass through.

Passing through

The pores of such membrane material are so small that they are measured in Angstrom (10-10 m), and pressure is required to force the liquid through them. In fact, the pores in the membranes used for nanofiltration and reverse osmosis are so small that they cannot be seen even with a scanning electron microscope.

Types of membrane filtration

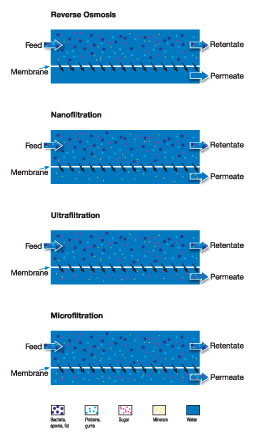

Reverse osmosis (RO)

Reverse osmosis uses the tightest possible membrane in liquid separation. In principle, water is the only material that can permeate the membrane. All other materials (salts, sugars, etc.) will be unable to pass through)

Nanofiltration (NF)

Nanofiltration is not as fine a separation process as reverse osmosis, and uses membranes that are slightly more open. Nanofiltration allows small ions to pass through while excluding larger ions and most organic components.

Ultrafiltration (UF)

Ultrafiltration involves membranes in which the pores are larger and the pressure is relatively low. Salts, sugars, organic acids and smaller peptides are allowed to pass, while proteins, fats and polysaccharides are not.

Microfiltration (MF)

In microfiltration, suspended solids, bacteria and fat globules are normally the only substances not allowed to pass through.