商業規模釀造

Alfa Laval has a vast range of proven commercial brewing equipment and solutions to meet your efficiency, reliability and consistency requirements on an industrial scale. Our process expertise, along with our professional systems and technologies, new or retrofit, enable you to fine-tune delicate production balances in the commercial brewing process to boost yields, use less energy and water, reduce waste and produce remarkable beers that send out a strong message about your brand’s uniqueness.

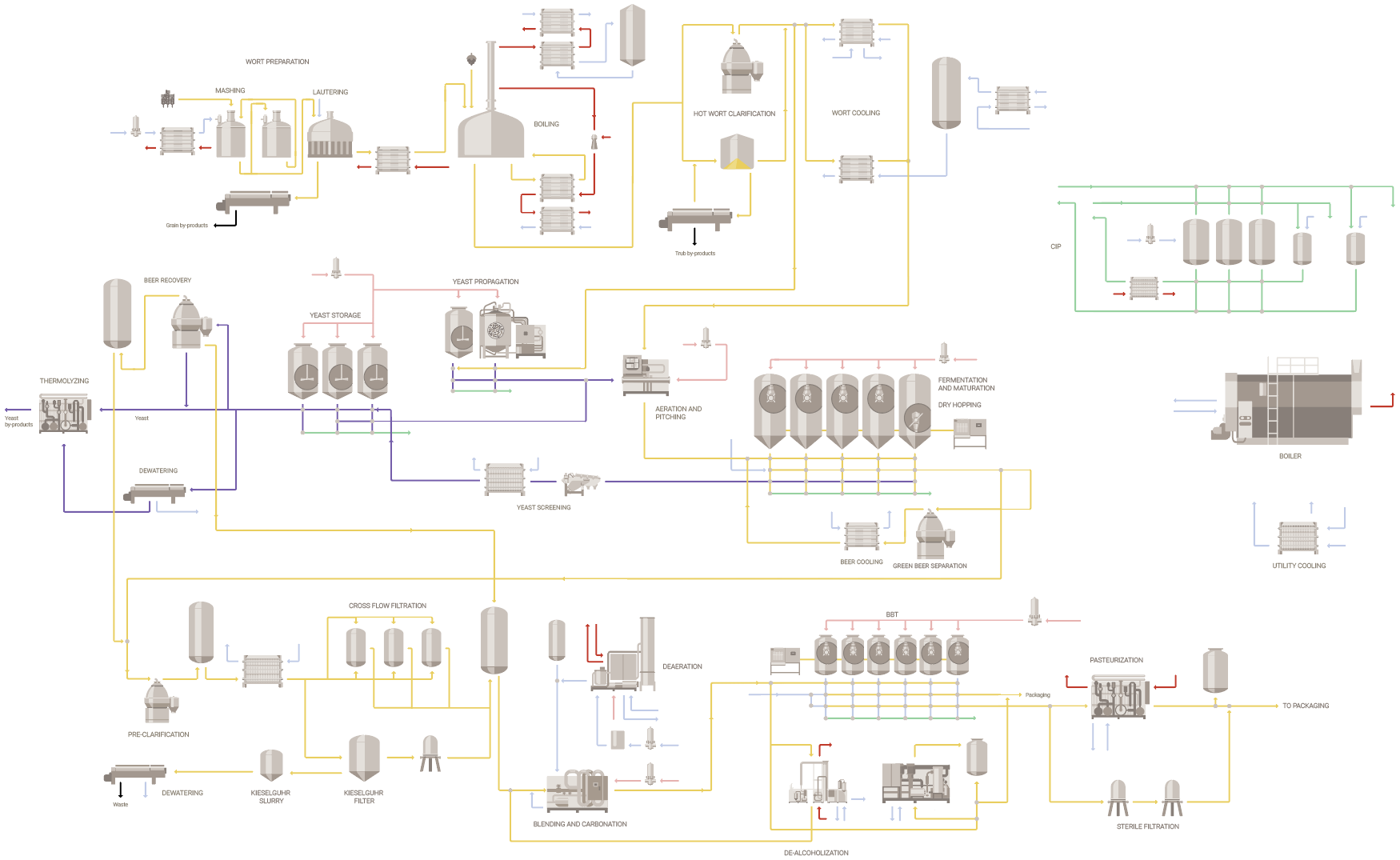

Commercial brewing solutions - Brewing on an industrial scale

- Professional brewing solutions for brewers, based on proven brewery techniques

- Proven track record of improved yield and reduced water and energy consumption

- Flexibility that enables you to quickly respond to new trends in the brewing industry

- A global service network of professional brewing specialists to support you with process expertise, spare parts and commercial brewing equipment

Our commercial brewing solutions, from individual components and process modules to turnkey projects, are designed and manufactured to provide tight control over your brewing, while allowing you the flexibility to help brew remarkable beer.

Join our webinars

Our brewery experts look forward to sharing with you our knowledge and passion.

為您的商業釀造過程提供經過驗證的解決方案

使用我們的釀造設備,解決釀造過程中的挑戰

從釀造車間到包裝,改善操作是釀酒商的日常事務。 麥芽汁產量、啤酒損失或用水量方面的增量改善可以長期節省大量成本。 瞭解我們的釀造工藝專業知識、解決方案和每個工藝塊的各個組件如何幫助避免和克服釀造過程中的常見問題。

釀造車間

回收麥芽汁,減少浪費,節約能源,提高啤酒廠的效率和衛生條件。

冷塊

回收啤酒,縮短發酵和成熟時間,改善酵母管理,取樣等。

過濾和處理

避免腐敗,提高啤酒品質,使產品多樣化。

公用設施

最佳化清潔順序,從而減少整體能源和化學品使用量。