燃氣燃燒

During the last decade, the major part of new-building LNG carriers have changed main propulsion system from steam turbine into Dual Fuel Diesel Electric (DFDE) propulsion. The use of DFDE engines or the new generation 2-stroke DF engines provides LNG ship-owners and operators with economical and environmentally sound alternatives to traditional systems. Combined with proven technology and simplicity in design makes the Alfa Laval GCU the clear choice for today’s LNG Carriers.

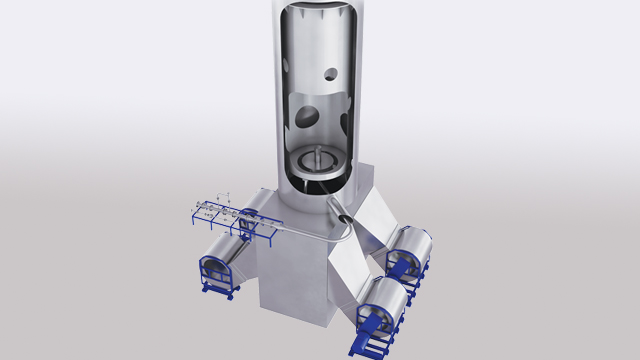

Efficient Gas Combustion Unit

- Simple and compact design without any moving parts inside the combustion chamber

- Combined combustion and dilution fans that do not require silencers or duct pipes

- All metallic combustion chamber with no refractory lining

- Electric ignites instead of an oil pilot and associated equipment

- Induct burner type that offers a robust and extremely reliable design

Part of a growing LNG portfolio

The Alfa Laval Gas Combustion Unit (GCU) is a central component of boil-off management strategy. It provides a reliable, simple and compact means of safely dealing with excess boil-off gas on LNG carriers with dual-fuel or low-speed dual-fuel engines.

The GCU is joined by inert gas generators, burners, boilers, heat exchangers and more to form an extensive portfolio of Alfa Laval solutions for use with LNG. As fuel choices and cargo needs grow even more specialized, more LNG solutions and other vessel-specific equipment will follow.

Alfa Laval Gas Combustion Unit

The Alfa Laval Gas Combustion Unit (GCU) is a critical unit. It ensures the effective and safe combustion of boil-off gas (BOG), which allows continuous and reliable operations on the LNG carrier.

Innovating at the Alfa Laval Test & Training Centre

At the Alfa Laval Test & Training Centre, the solutions and knowledge for working with LNG on board continue to develop. The facility’s 2800 m2 of testing space include a dedicated LNG process line with a full-size GCU. This unique R&D resource is providing deeper insights into both gas handling and combustion – not only for LNG, but also for other alternative fuels. The efforts will ensure safety and efficiency on tomorrow's more sustainable shipping.