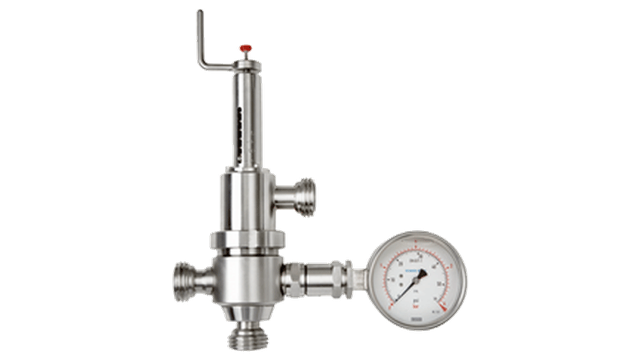

SB Tank Pressure Regulator

The Alfa Laval SB Tank Pressure Regulator maintains the working pressure in the vapour space, or at the top, of a process tank during filling, processing and emptying. It generally connects directly to the gas pipe or Cleaning-in-Place (CIP) pipe that leads in to the tank top, or is incorporated into a flow panel. This ensures process safety and effectiveness as well as safeguards product integrity.

Tank pressure regulator maintains and regulates top pressure on pressure tanks during filling, processing and emptying

- Reliable, constant tank pressure control

- Variable pressure setting

- Optimized cleaning

- Built-in pressure gauge

- Fully cleanable with Cleaning-in-Place system

This control valve typically regulates the pressure in tanks used in the dairy, food, beverage, brewery and many other industries. The valve easily integrates with an Alfa Laval SCANDI BREW® tank top system.

Secure tank top pressure control

Maintaining the working pressure at the tank top is critical. The tank pressure regulator makes sure that the pressure in the vapour space of a process tank is always at the optimal setting. This ensures the safety and effectiveness of your processes and safeguards product integrity.

Modular hygienic design

All pressure regulator components are made of high-quality hygienic materials that meet stringent food and beverage processing standards. Modular design provides the flexibility to meet most installation requirements. Hygiene is assured through the use of a CIP adaptor to provide full cleanability.

Product benefits

- Constant tank top pressure during filling, processing and emptying

- Reliable setting of working pressure

- Fully cleanable with CIP system

工作原理

Construction

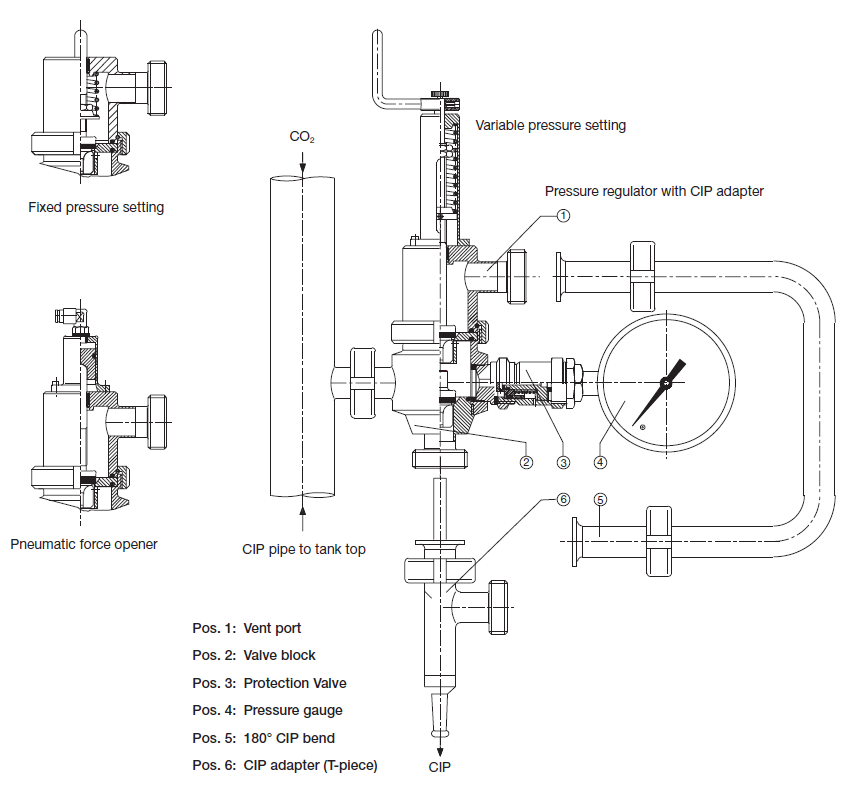

The tank pressure regulator consists of single valve unit incorporating a pressure exhaust valve, a pressure-supply valve and a connection for a pressure gauge. The pressure regulator can be supplied with a valve with different versions of the spring/regulating unit:

- Fixed setting (only one pressure)

- Variable setting

- Pneumatic actuator

The regulator can be integrated with a SCANDI BREW® tank top system.

Operating principle

The valve unit is supplied with either with a fixed setting or a variable setting, which adjusts the relieving pressure to the required working pressure in the tank. When tank top pressure exceeds the preset pressure, the regulator releases the gas through the vent port either for atmospheric discharge or for collection. If the tank top pressure decreases, gas is supplied through the gas supply connection at the bottom.

Cleaning-in-place (CIP)

The tank pressure regulator requires cleaning between every batch. It is incorporated into the tank CIP procedure by means of the optional CIP adaptor. Before cleaning, the CIP adaptor is mounted onto the pressure regulator; it forces open the gas supply valve and pressure relief valve and enables them to be fully cleaned. During the CIP procedure, all functions are blocked. See the schematic drawing of the regulator.

Options

- CIP adaptor (T-piece and 180°bend)

- Pressure gauge

- Protection valve for pressure gauge when CIP pressure exceeds range for pressure gauge

- Mounting brackets

- Force opener

- Mounting bracket on reverse side of valve block

Part of a broad valve range

Alfa Laval offers a comprehensive range of valves intended for hygienic applications in the dairy, food, beverage,home care, personal care, biotechnology and pharmaceuticals.

For a broader valve range, explorer the different product categories: ball valves, butterfly valves, control/check valves, diaphragm valves, double seal valves, double seat valves, safety valves, sample valves, shutter valves and single seat valves.

十大提示 - 閥門

以下是一些提示和服務視訊,說明了如何將衛生閥門保持在最佳狀態

Food Logic

阿法拉伐的衛生設備結合了高效能和溫和處理,以保存敏感成分。 跟上食品行業的發展趨勢,解決四大關鍵挑戰;以具有競爭力的價格向消費者提供食品,充分利用原材料,減少浪費和排放,以及提供安全衛生的食品。

產品目錄

最新的「近在咫尺」線上版本