Foodec Oil Plus

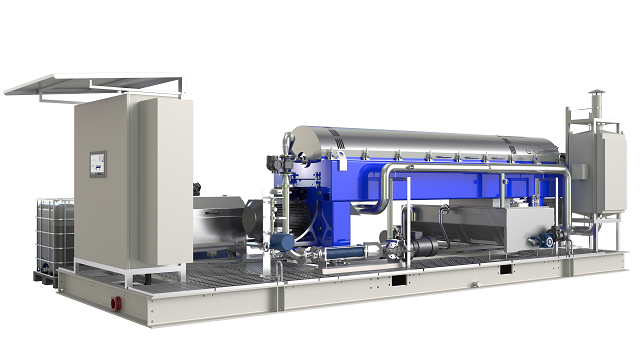

Alfa Laval Foodec Oil Plus decanters are ideal for extracting oil in processes such as fish rendering, meat, and poultry processes. With its innovative design, Oil Plus decanters efficiently achieves maximum extraction of valuable oil, ensuring maximal utilization of raw material. It is easy to operate and maintain, giving you minimal payback time and total cost of ownership. Available a standalone component or a plug-and-play skid, that can easily integrate into your current plant and process.

Experience the highest possible yield and clean discharge

- Long retention time, maximizing oil extraction and uptime

- Validated and proven technology, reaching up to 99.5 Vol.% oil/fat purity, requiring little further processing

- Simplified process setup reduces the need for peripheral decanter oil equipment such as pumps, tanks, piping, etc.

- Low total cost thanks to reduced energy consumption and maintenance costs, often resulting in a pay-off time of less than one year

- Stable operation with open outlets maintains a stable interphase even with fluctuations in feed flow or composition

- Available as a standalone component or a plug-and-play skid, needing minimal change in your existing process

How it works

This Alfa Laval decanter centrifuge is intended for a three-phase suspension, where one discharge phase is for oil only. The working principle is similar to a skimmer. The incoming feed is effectively separated into oil and wet slurry.

The product is fed into the bowl through an inlet tube and is accelerated by the inlet rotor. Separation takes place in a horizontal cylindrical bowl equipped with a screw conveyor that is purpose-built for efficient oil recovery. Centrifugal force separates the oil from the feed slurry, making the (lower density) oil accumulates at the liquid surface, while the solids are kept in suspension and are discharged, as a slurry, in the conical end together with the water. Oil extraction takes place along the entire length of the cylindrical part of the bowl.

Fish oil processing

In the rendering method of oil extraction, adding a Foodec Oil Plus decanter can increase the oil extraction rate by up to 3%, while also reducing fat in dry matter (FiDM) by at least 2%—with even greater fat reduction observed in the final fish meal.

This not only increases the revenue from the oil fraction, but also raises the market value of the protein due to the lower fat content. As an added benefit, the extracted oil is so clear that further processing in a high-speed separator can be kept to a minimum.

Service

定期維護保養對臥式離心機Foodec的運轉效能與衛生安全,極其重要。依據產線運轉時間、原料類型、製程溫度、循環清洗(CIP)次數等,Alfa Laval建議:

- 至少每4~6個月檢查一次臥式離心機

- 至少每年做一次年度保養服務

依設備狀況,Alfa Laval專業的售後服務工程師可在現場,或是Alfa Laval技術服務中心執行點檢與維修服務工作。但轉鼓與螺旋傳動軸的維修保養,因工序專業需求與複雜度考量,需在Alfa Laval技術服務中心內完成。

隨著數位技術日益增進,遠端技術支援與設備監測服務等互聯服務,可延長設備維修保養間隔。建議您可將互聯服務納入服務合約(Service Agreement),為您的設備打造客製化服務方案。

聯絡我們立即為您的設備訂製專屬服務。