2016-05-12 Product News

Alfa Laval to launch new tool to help customers minimize total cost of ownership of decanters in waste water business

At this year's IFAT, the leading trade fair for water, sewage and raw materials management, Alfa Laval will launch a new cost calculation tool to help customers minimize their total costs over the life cycle of the decanters, leveraging on Alfa Laval’s unrivalled knowledge and expertise in waste water process applications.

The tool uses maintenance, repair and operational costs (MRO) data to calculate total cost structure of running operations. After conducting a cost calculation, Alfa Laval experts sit down with customers and analyze the data thoroughly, applying their knowledge and expertise to identify improvement opportunities.

“The results can be sometimes surprising,” says Martin Leodolter, Service Manager Industry at Alfa Laval Mid Europe. “In the waste water business, two important drivers are the costs of disposal and of polymer. Having a better understanding of the cost structure is crucial to find solutions that can minimize overall costs.”

Based on the data, Alfa Laval experts can identify and implement measures to optimize performance of the customers’ decanters to improve cake dryness and decrease polymer consumption.

“Even a small increase in cake dryness and/or a small decrease in polymer consumption can lead to a significant cost reduction. The significance of a few percentage points is often underestimated”, continues Martin Leodolter.

Subsequent suggestions for improvements can range from a simple fine-tuning of the decanter’s settings to the establishment of maintenance programs or equipment upgrades. In cases where the detailed analysis of results reveals unusually high consumption of energy, polymer costs or other running costs, Alfa Laval offers in-depth monitoring services to investigate these anomalies. For example, a Condition Audit to study the mechanical condition of the equipment, or a Performance Audit to quantify how the actual performance of the equipment. Both these services provide the customer with fact-based insights and indications on how to improve performance.

“Our new life cycle cost calculation tool for decanters is a powerful way for customers to streamline their waste water operations,” concludes Martin Leodolter.

Besides the Condition and Performance Audits mentioned above, Alfa Laval offers numerous other services to support customers in this industry. The Alfa Laval 360° Service Portfolio contains services and solutions for every aspect of the customer’s equipment and every phase of its life cycle including start-up, maintenance, support, improvements and monitoring services.

Learn more about the Alfa Laval 360° Service Portfolio

About Alfa Laval

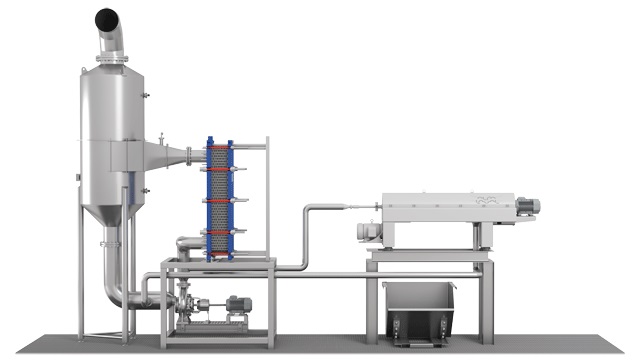

Alfa Laval is a leading global provider of specialized products and engineering solutions based on its key technologies of heat transfer, separation and fluid handling.

The company’s equipment, systems and services are dedicated to assisting customers in optimizing the performance of their processes. The solutions help them to heat, cool, separate and transport products in industries that produce food and beverages, chemicals and petrochemicals, pharmaceuticals, starch, sugar and ethanol.

Alfa Laval’s products are also used in power plants, aboard ships, oil and gas exploration, in the mechanical engineering industry, in the mining industry and for wastewater treatment, as well as for comfort climate and refrigeration applications.

Alfa Laval’s worldwide organization works closely with customers in nearly 100 countries to help them stay ahead in the global arena. Alfa Laval is listed on Nasdaq OMX, and, in 2015, posted annual sales of about SEK 39.7 billion (approx. 4.25 billion Euros). The company has about 17 500 employees.