永續食品

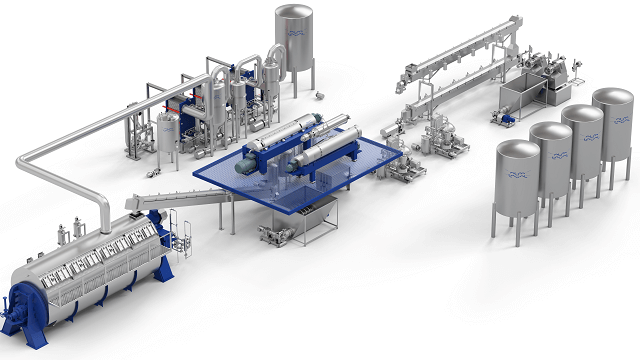

Alfa Laval was founded on sustainable food production, and every day we actively make sustainable operations in all food industries a reality. Our innovative solutions were created in response to food producers’ focus on enhancing the processing of raw materials, achieving higher yields while consuming less water and energy.

We explore and realize the upcycling potential of by-products that currently are not fully utilized. The continuous development of our solutions pushes the boundaries of technical feasibility, allowing food producers to make much more food with the same or, ideally, with even fewer resources.

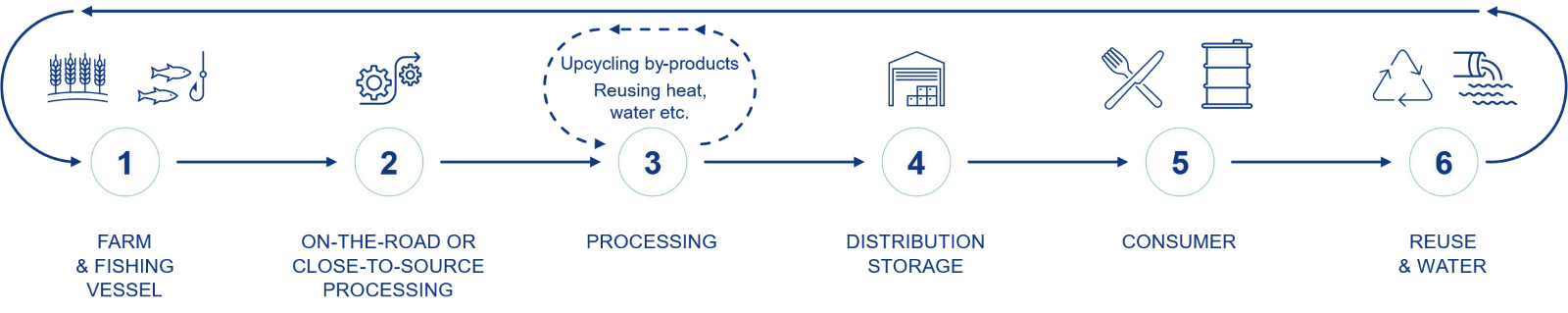

From Farm to Fork

Alfa Laval’s solutions support big parts of the value chain for food and beverages with a predominant, but not exclusive focus on processing and reuse & water.

A global push for more sustainable food

In less than a generation, the world will require up to 70 percent more healthy, nutritious and affordable food for a growing population – and ideally, it will be produced with far less energy, water and raw materials. But in recent years, the UN has recorded less-than-satisfactory progress in advancing sustainable development in the pursuit of its goal number 2, “Zero Hunger.”

Meanwhile, global food producers are responding to consumer preferences for sustainable food by minimizing the environmental footprint of their entire supply chains – from Farm to Fork. And since the scope of Science-based Targets was extended from Climate to Nature – with considerations for Freshwater, Land and Biodiversity – food producers have come to dominate the group of early-adopters.

Yield

Industrial food processors primarily focus on bulk production with maximum uptime – producing large quantities of quality food at an affordable price. Alfa Laval’s competence in the optimization of food production traces its roots back to the company’s inception when the primary focus was on the separation of cream from milk.

Alfa Laval remains deeply involved in the Dairy industry, showcasing many instances where we have enabled dairy producers to increase their yield, while contributing to the upcycling of by-products into food suitable for human consumption.

A notable example is whey – a highly protein-rich and nutritious by-product from cheese production. Previously it was fed to pigs. Now, we enable customers to recover high-quality protein instead or use it to enrich beverages.

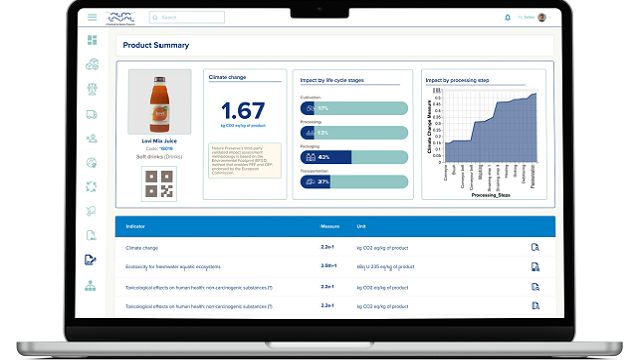

Condition monitoring prevented the product loss of 288,000 bottles

Ensuring high uptime is a first priority at Britvic’s production plants. At their plant in Rugby, Great Britain, Britvic successfully prevented pump failure, optimized asset performance and ensured continuous production by using Alfa Laval Analytics for online condition monitoring.

The real deal: improving efficiency in the brewing of craft beers

When an independent brewery in Northern Europe was looking to replace the heat exchanger it used for cooling wort – a central part of brewing operations – they chose an H4 from Alfa Laval’s Hygienic line. They are now producing their signature wild yeast beers with higher hygiene and greater efficiency than ever.

Olive Oil Booster delivers top quality, high performance and sustainability

For Italian olive oil producer, Sacco Oliveti quality is paramount. The family-owned company has been producing extra virgin olive oil for decades from the distinctive Peranzana olives, grown across 6,500 hectares of ancient olive groves in Puglia.

Water

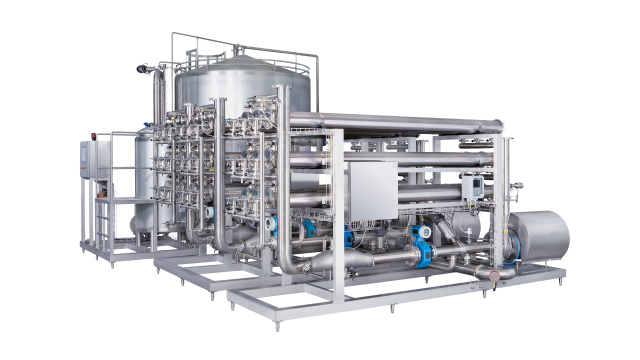

Changing weather patterns caused by ongoing climate changes are resulting in erratic rainfall so that food producing areas are often affected by either too much or insufficient water. With growing public concern over the adaptation to the impacts of climate changes, food producers are increasingly considering the availability of the right quality of water and how to adopt a circular water system in their food processing lines.

At Alfa Laval, we offer numerous solutions that enhance efficiency in the utilization and consumption of processing water; for instance, for essential tasks such as cooling and cleaning that is required for hygienic production.

Our diverse range of solutions will also enable industrial food producers to treat, polish and purify wastewater. The treated wastewater can be reinjected as processing water or released into surface water, contributing to the restoration of local watersheds.

Global drinks giant blazes a trail on sustainable water use

The company estimates that a 132 percent water replenishment rate per bottle produced is currently being achieved at its manufacturing and bottling plants across the Philippines through water management schemes, operational efficiencies, and community water projects.

Water and energy savings pay back plant upgrades in only four months

For decades, the production facilities of a leading South African ice cream producer had expanded, using various component suppliers and leaving the service and maintenance tasks quite complex, time consuming and with a costly stock of many different spare parts.

Tank cleaning upgrade cuts water consumption by 17

In light of increasing pressures on freshwater resources, a leading US based brewery group has committed to increasing water efficiency and cutting water consumption in its operations.

Energy efficiency

As temperatures continue to rise on the planet, the imperative to reduce greenhouse gas emissions is intensifying in the drive to reverse global warming. With a policy response taking shape and becoming established in this area, companies are increasingly faced with a requirement to comply with regulations and document lower emissions throughout their supply chains.

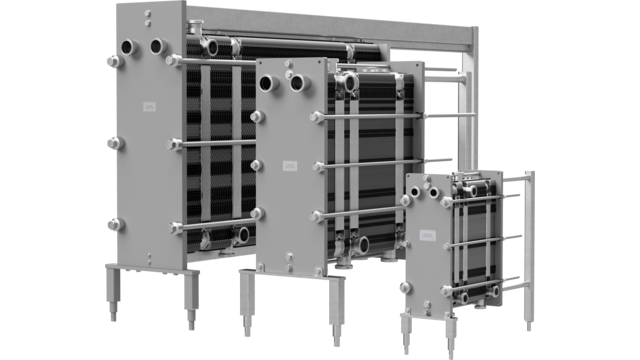

Energy efficiency has long a been a fundamental quality of Alfa Laval’s solutions. We continue to build on the legacy of our separation technology, and today the hermetic design of our disc-stack centrifuges for food production means that they are more than 50 percent more energy efficient than the leading competitive solutions in the market. Our solutions empower producers to convert from fossil fuels to renewable energy.

Optimizing dry rendering processes for 40% in energy savings and improved protein and fat quality

Proteg SpA approached Alfa Laval to improve product quality while reducing energy costs and environmental emissions. The request? A higher protein content to raise the sales price of protein meal for pet food and higher quality fat for use in biofuel. The solution? Adding the Alfa Laval Dry Rendering Optimizer, a highly efficient, cost-effective system, to the existing dry rendering process lines, increasing protein content in meal by 3–5% and fat yield by more than 10%

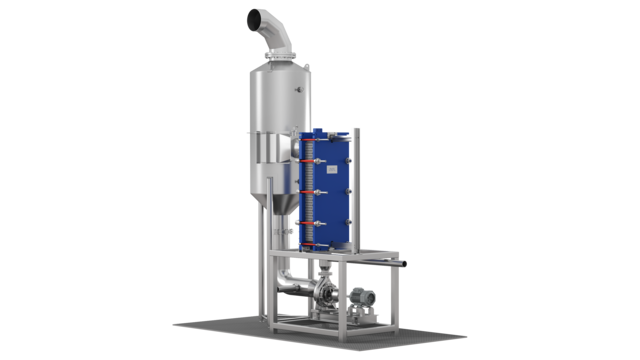

Improve fishmeal quality with energy-efficient systems

Marine Functional Vietnam (MFC), a leading manufacturer of protein hydrolysates for food and animal feed additives, set out to increase its fish oil and fishmeal quality, while cementing a leadership position in sustainability. MFC partnered with Alfa Laval, based on its sustainability focus, broad equipment portfolio, and local service and support. The result? A 40% reduction in energy use, 80% reduction in odour emissions and a stickwater concentration up to 55% before requiring further treatment.

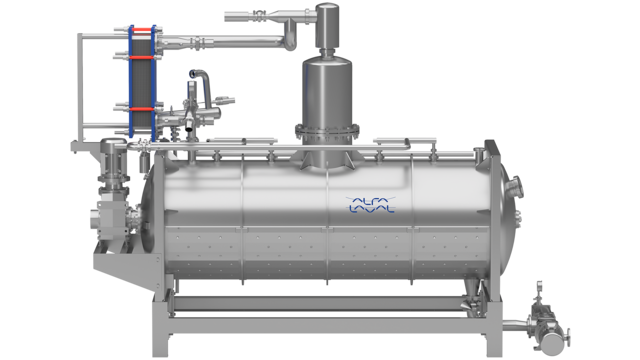

Chelsea Sugar reduces carbon emissions with new Alfa Laval evaporation system

Switching to a more sustainable evaporation solution will enable the Chelsea Sugar Factory to cut carbon emissions and reduce its energy consumption while simultaneously optimizing the efficiency of its operations. Founded in 1884, NZ Sugar Company (Chelsea) is one of the country’s top 100 companies. Its products are derived from natural sugar cane and the factory still operates from its original site on the seafront at Birkenhead, a suburb of Auckland.

By-products

Almost a third of all food – around 1.3 billion tonnes – is lost between Farm and Fork – every year. This translates into 14 percent or 4.9 trillion m3 of water withdrawn for the very thirsty agricultural sector. Considering the methane produced by decaying food, these losses are estimated to make up 16 percent of total greenhouse gas emissions.

Alfa Laval routinely collaborates with food producers who have by-products from their food production, which they suspect may be underutilized.

Numerous by-products derived from food production contain valuable nutrients, such as proteins. These can be recovered and even upcycled and transformed into suitable ingredients for human consumption, used as feed for livestock, or repurposed for non-food products, such as biofuels. The collaboration with Alfa Laval often leads to the development of new and valuable revenue streams for food producers.

Value from leftovers gets to the bones of the circular economy

A partnership between UK agri-food tech company, Elemental, and Alfa Laval has resulted in the recovery of additional value-added products from animals processed by a meat producer. Alfa Laval’s separation and evaporation systems are central to ground-breaking food-processing technology that recovers valuable proteins, fats, and minerals from the by-products of the meat industry.

Circular olive oil processing extracts valuable pomace olive oil from leftovers for producers in Spain

The olive oil producer, San Miguel Arcángel S.A., in Spain uses evaporation systems and decanter separation technology to get much more from their olives – harvesting valuable antioxidants and pomace olive oil from the leftovers of the olive oil extraction process, as well as cleaning wastewater for re-use.

Here for the beer: upcycling sustainable protein from brewer’s spent grain

Sustainable sources of high-quality protein are essential in meeting the ever-increasing global demand for healthy, affordable, and nutritious food. Alfa Laval’s expertise within protein makes it an ideal technology and solutions.