手工精釀

Add our expertise and professional brewing equipment to your energy for craft brewing. Alfa Laval can help you on your unique craft brewing journey and overcome challenges. It may be the need for quality consistency, growing production target , or whether you could, actually, be doing something better? Finally, getting new equipment installed right the first time around. We have the right craft brewing equipment as well as the experience, knowledge, and shared passion to help you.

Amazing, stand-out beers

- Solutions for all craft brewers, by those who know their trade

- Proven track record of improved yield and reduced water and energy consumption

- Flexibility to enable you to quickly tap into new trends in craft brewing

- A global service network of craft brewing specialists to support you with brewing equipment, systems and expertise.

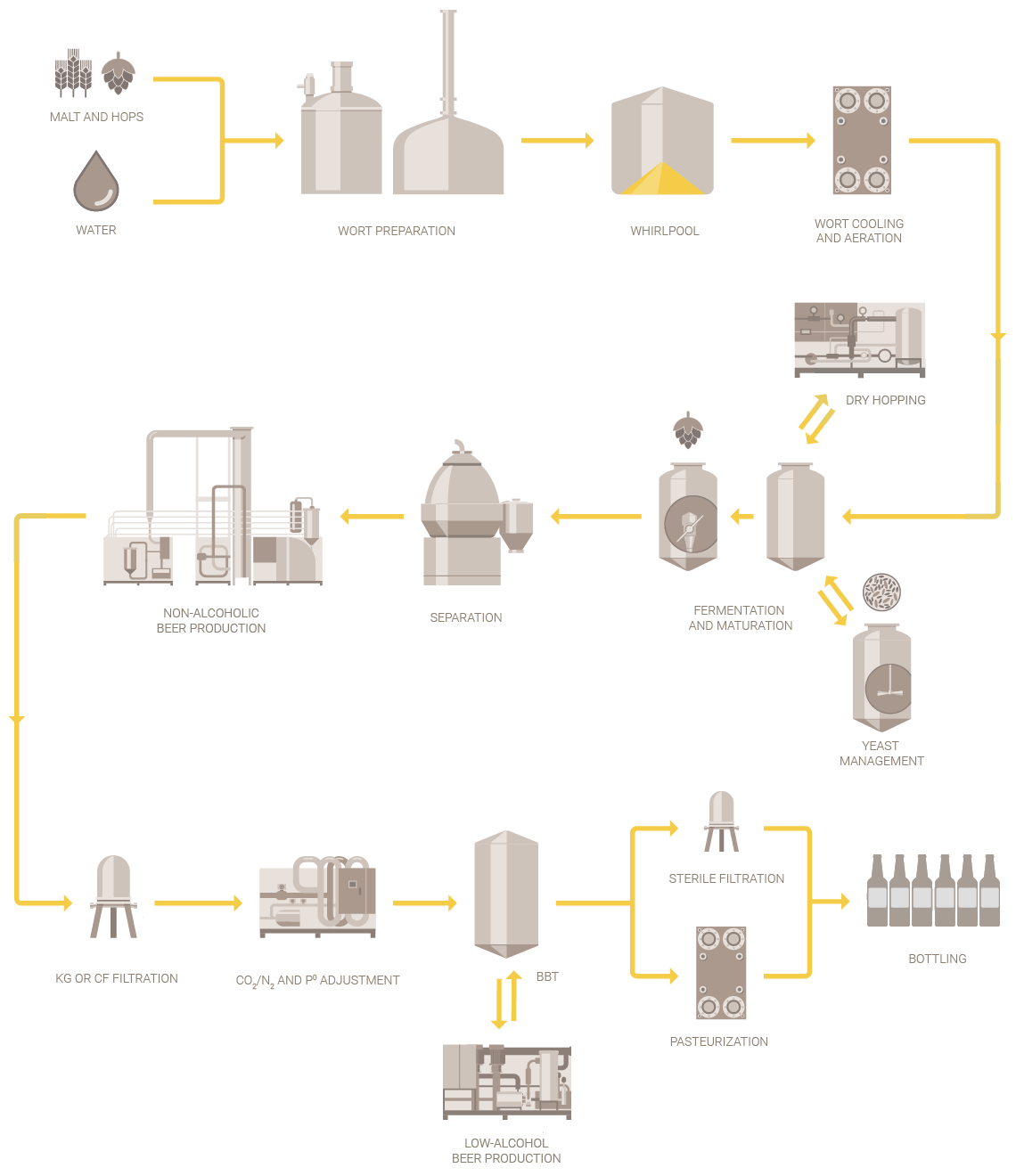

Craft brewing process

使用我們的釀造設備,解決釀造過程中的挑戰

從釀造車間到包裝,改善操作是釀酒商的日常事務。 麥芽汁產量、啤酒損失或用水量方面的增量改善可以長期節省大量成本。 瞭解我們的釀造工藝專業知識、解決方案和每個工藝塊的各個組件如何幫助避免和克服釀造過程中的常見問題。

Brewhouse

Recover wort, reduce waste, save energy and improve brewhouse efficiency and hygiene.

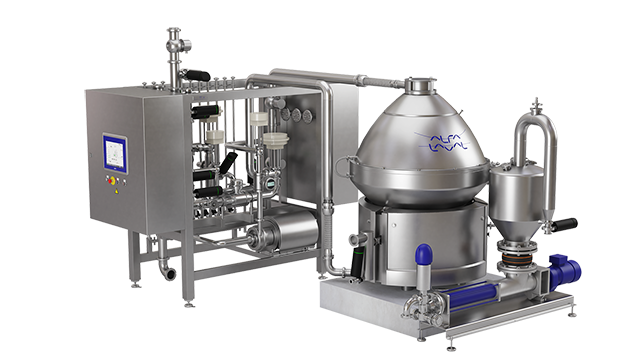

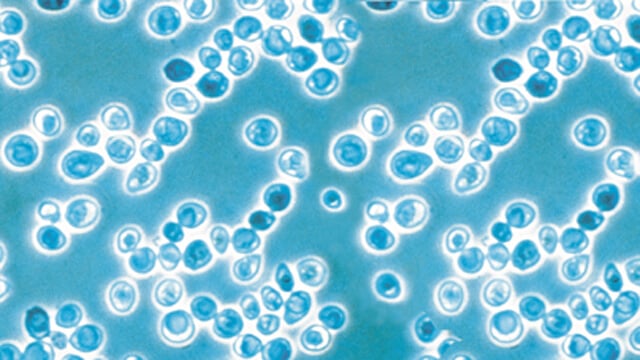

Coldblock

Recover beer, shorten beer fermentation and maturation time, improve yeast management, sampling and more in the coldblock.

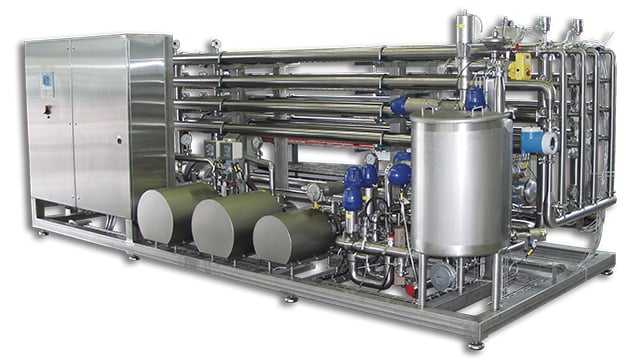

Filtering and treatment

Avoid spoilage, improve beer quality and diversify your products.

Preparation of lines & Cleaning

Optimize cleaning and preparation of lines.

Craft beer brewing

The craft of making beer blends complex processes with creative artistry. Bridging the gap between brewing theory and practical craft brewing comes from the experience to spot signs of trouble and the know-how to respond to them. This is where combining expertise can yield benefits stretching from the brewhouse to packaging. Issues can be controllable and avoidable, given the right brewing equipment and the right application. See our process knowledge and craft brewing solutions.

Happy brewers

According to Art Oestrike, president at Jackie O's, "Barrel ageing beers is a fickle business. You take this big, beautiful imperial stout or barley wine and throw it into a freshly dumped bourbon barrel and let it sit in our warehouse. A year and a half after packaging it, they start to turn sour. They don't taste good."

Watch the video to hear how Flexitherm Mini 'flipped the barrel aging programme on its head'.

When quality comes first

Discover well-designed solutions for craft brewers.